The Unsung Hero of Manufacturing: My Journey with ERP Manufacturing Planning Systems

Hello there, fellow explorers of the industrial world! Pull up a chair, grab a coffee, and let me tell you a story. It’s a story not about grand inventions or revolutionary products, but about something far more fundamental – something that quietly, yet profoundly, changed the way I saw manufacturing, and ultimately, made it work. I’m talking about the ERP Manufacturing Planning System, an unsung hero that has transformed countless factories from chaotic jumbles into finely tuned machines.

You see, for years, I worked in the trenches of manufacturing. I’ve seen it all: the frantic phone calls, the mountains of paperwork, the last-minute changes, and the sheer exasperation when a critical part was missing, holding up an entire production line. It was a world of reactive decisions, where "firefighting" was a daily sport, and true planning often felt like a luxury we couldn’t afford.

Back in the Day: The Pre-ERP Mayhem

Let me paint a picture for you. Imagine a bustling factory floor. Orders come in, and someone – usually a production manager with a heroic capacity for mental acrobatics – tries to figure out what needs to be made, what materials are needed, and when.

This usually involved:

- A dozen different spreadsheets: One for inventory, one for orders, one for supplier contacts, one for production schedules. None of them truly "talked" to each other.

- A lot of yelling: "Where’s that component for Job #123?" "Did we order enough steel for next week?" "Why is the paint shop sitting idle?"

- Inventory guesswork: We’d often have too much of one thing gathering dust, and not enough of another, causing urgent (and expensive) rush orders.

- Missed deadlines: Despite everyone working their hardest, predicting delivery dates was like reading tea leaves. Our customers often felt the brunt of our internal disorganization.

- Siloed information: The sales team promised a delivery date without knowing the actual production capacity. The purchasing team bought materials without real-time insight into what was actually consumed on the floor.

It was, frankly, exhausting. We were good people, working hard, but the system – or lack thereof – was constantly tripping us up. We needed a conductor for our industrial orchestra, but all we had were individual musicians playing their own tunes.

What Exactly is an ERP Manufacturing Planning System, Anyway? (The "Aha!" Moment)

Then, a new whisper started making its way around the industry: "ERP." At first, it sounded like just another tech buzzword. "Enterprise Resource Planning," they called it. My eyes would glaze over. But as I dug deeper, I realized it wasn’t just a buzzword; it was the solution we desperately needed.

Think of an ERP Manufacturing Planning System not as a single piece of software, but as the central nervous system of your entire manufacturing operation. Imagine all those disparate spreadsheets, all those frantic phone calls, all that siloed information, suddenly connected, integrated, and speaking the same language.

In simple terms, an ERP system for manufacturing brings together all the critical business functions – from accepting an order to shipping the finished product – into one unified platform. It’s like having a single, incredibly smart dashboard that shows you everything: what you have, what you need, what you’re making, and when it will be ready.

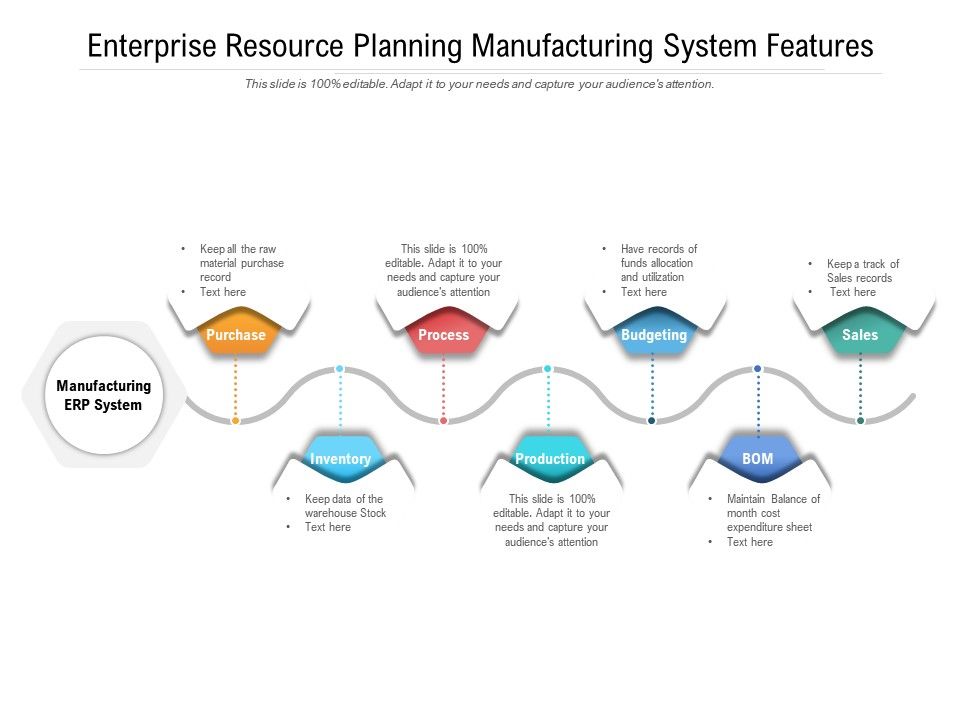

The Core Pillars: How ERP Transforms Planning

Let’s break down some of the key areas where an ERP system truly shines in manufacturing planning:

- Material Requirements Planning (MRP): This was a game-changer for us. Instead of guessing, the ERP system would look at our sales orders, our bill of materials (BOMs – the "recipe" for each product), and our current inventory. It would then automatically tell us exactly what raw materials and components we needed to order, and when to order them, to meet production schedules. No more over-ordering, no more running out!

- Production Scheduling: Remember the chaos of trying to manually schedule jobs across different machines and departments? An ERP system takes into account machine availability, labor resources, tool requirements, and material arrival dates. It creates an optimized production schedule, minimizing idle time and bottlenecks. It’s like having a master chess player planning every move on the factory floor.

- Capacity Planning: This is where we learned to say "yes" or "no" to new orders with confidence. The ERP system could analyze our current workload and machine capacity, telling us if we had the resources to take on a new, large order without jeopardizing existing commitments. It helped us avoid over-promising and under-delivering.

- Inventory Management: This went beyond just counting what we had. An ERP system tracks inventory in real-time – as materials arrive, as they’re consumed in production, and as finished goods are shipped. It helps optimize stock levels, reducing carrying costs and minimizing the risk of obsolescence. We knew exactly what was on the shelves, where it was, and how long it had been there.

- Quality Control Integration: Good manufacturing isn’t just about making things fast; it’s about making them right. Modern ERPs can integrate quality checks into the production process, tracking non-conformances, managing inspections, and even linking back to supplier performance.

- Shop Floor Control: This gives you real-time visibility into what’s happening on the factory floor. Operators can clock into jobs, record material usage, and report production progress directly into the system, often via tablets or touchscreens. This immediate data flow provides an accurate picture of production status at any given moment.

- Data Analytics & Reporting: Perhaps the most powerful aspect. With all this data flowing into one system, an ERP provides powerful reporting and analytics tools. We could generate reports on production efficiency, material waste, on-time delivery rates, and more. This wasn’t just data; it was insight that helped us continuously improve.