From Chaos to Control: My Journey with ERP Asset Maintenance Scheduling

(Meta Description: Discover how ERP Asset Maintenance Scheduling transformed my operations from reactive chaos to proactive efficiency. A personal story for beginners looking to optimize asset management and reduce downtime.)

Chapter 1: The Good Old (Bad Old) Days – A Maintenance Manager’s Nightmare

Picture this: it’s 3 AM, my phone is buzzing off the hook, and I’m staring at the ceiling, dreading the call. Another critical piece of equipment has broken down – unexpectedly, of course. This wasn’t a rare occurrence; it was a Tuesday for me, John, a seasoned (and perpetually stressed) operations manager in a bustling manufacturing plant.

For years, my team and I operated in what I affectionately (and ironically) called "firefighting mode." Our asset maintenance scheduling? It was a chaotic dance between outdated spreadsheets, hastily scribbled notes on clipboards, and the sheer memory of my most experienced technicians. We had a basic preventive maintenance (PM) schedule for some critical assets, sure, but it was often overridden by more urgent, reactive repairs.

I remember one particularly dreadful week. First, the main compressor went down, halting an entire production line for half a day. We scrambled to find spare parts, only to discover our inventory records were wildly inaccurate. Then, while that was being fixed, a key robotic arm started acting up. Instead of a planned, calm intervention, it became a desperate rush to prevent a second line from grinding to a halt. The cost in lost production, overtime, and expedited parts was astronomical. Not to mention the impact on team morale – everyone was constantly on edge, exhausted, and feeling like they were always one step behind.

My desk was a graveyard of paper work orders, some completed, some lost, some waiting for parts that might or might not be in stock. Analyzing asset performance was a pipe dream; we barely had time to log what we’d done, let alone glean insights from it. We were managing our assets, but it felt more like they were managing us. I knew, deep down, there had to be a better way. This wasn’t just inefficient; it was unsustainable.

Chapter 2: A Glimmer of Hope – Discovering ERP for Asset Management

The turning point came during an industry conference. I was listening to a panel discussion about "digital transformation" and "operational efficiency," terms that sounded a bit like corporate jargon to my tired ears. But then, one of the speakers started talking about something called ERP Asset Maintenance Scheduling. He described a system that centralized all asset information, automated maintenance planning, tracked parts, and even predicted potential failures.

My ears perked up. Could this be the answer to my sleepless nights and overflowing inbox? I approached him after the session, skeptical but intrigued. He explained that ERP, or Enterprise Resource Planning, isn’t just for finance or HR; it has powerful modules specifically designed for managing physical assets – often referred to as Enterprise Asset Management (EAM) or Computerized Maintenance Management Systems (CMMS) within a broader ERP framework.

He spoke about moving from reactive to proactive maintenance, extending asset lifespan, and making data-driven decisions. It sounded like a utopia compared to my current reality. I decided then and there that I needed to investigate this further. This wasn’t just about fixing broken things; it was about building a resilient, predictable operation. This was about finally taking control.

Chapter 3: Diving Deep – What Exactly is ERP Asset Maintenance Scheduling?

So, what exactly is this magical system that promised to turn my chaos into control? At its core, ERP Asset Maintenance Scheduling is a sophisticated software solution that integrates maintenance activities with an organization’s overall Enterprise Resource Planning system. Think of an ERP as the central nervous system of a business, and the asset maintenance module as the part that ensures all your critical equipment and facilities are running smoothly.

Here’s a breakdown of what I learned it could do, and how it differs from a simple spreadsheet:

- Centralized Asset Register: Imagine having a single, digital record for every single asset in your facility – from a small pump to a massive production line. This record includes its purchase date, serial number, warranty information, location, specifications, and a complete service history. No more hunting for manuals or trying to remember who worked on what last.

- Automated Maintenance Planning & Scheduling: This was the game-changer for me. Instead of manually trying to juggle tasks, the ERP system allows you to define different types of maintenance strategies:

- Preventive Maintenance (PM): This is the backbone. Based on manufacturer recommendations, operating hours, or calendar dates, the system automatically generates work orders for routine inspections, lubrication, and parts replacements before a breakdown occurs. For instance, after 500 hours of operation, the system knows to schedule a service for our main conveyor belt.

- Predictive Maintenance (PdM): This is the next level. By integrating with sensors (IoT devices) on equipment, the ERP can monitor real-time conditions like vibration, temperature, or pressure. If a deviation is detected, the system can alert us or even automatically generate a work order for inspection, allowing us to address issues before they escalate into failures. Imagine getting an alert that a motor bearing is showing early signs of wear, giving you weeks to plan its replacement, rather than a sudden catastrophic failure.

- Corrective/Reactive Maintenance: While the goal is to minimize this, unexpected breakdowns still happen. The ERP system streamlines the process for reporting, creating, and tracking these urgent work orders, ensuring nothing falls through the cracks and resources are allocated efficiently.

- Work Order Management: From creation to completion, the system manages the entire lifecycle of a work order. It can assign tasks to technicians, track progress, record labor hours, and link to necessary parts. Technicians can access work orders on mobile devices, update statuses, and add notes in real-time.

- Inventory and Spare Parts Management: This solved another major headache. The ERP system tracks all spare parts, their locations, quantities, and reorder points. When a work order requires a specific part, the system checks availability and can even trigger an automatic purchase order if stock is low. This drastically reduces stockouts and ensures we have the right parts at the right time.

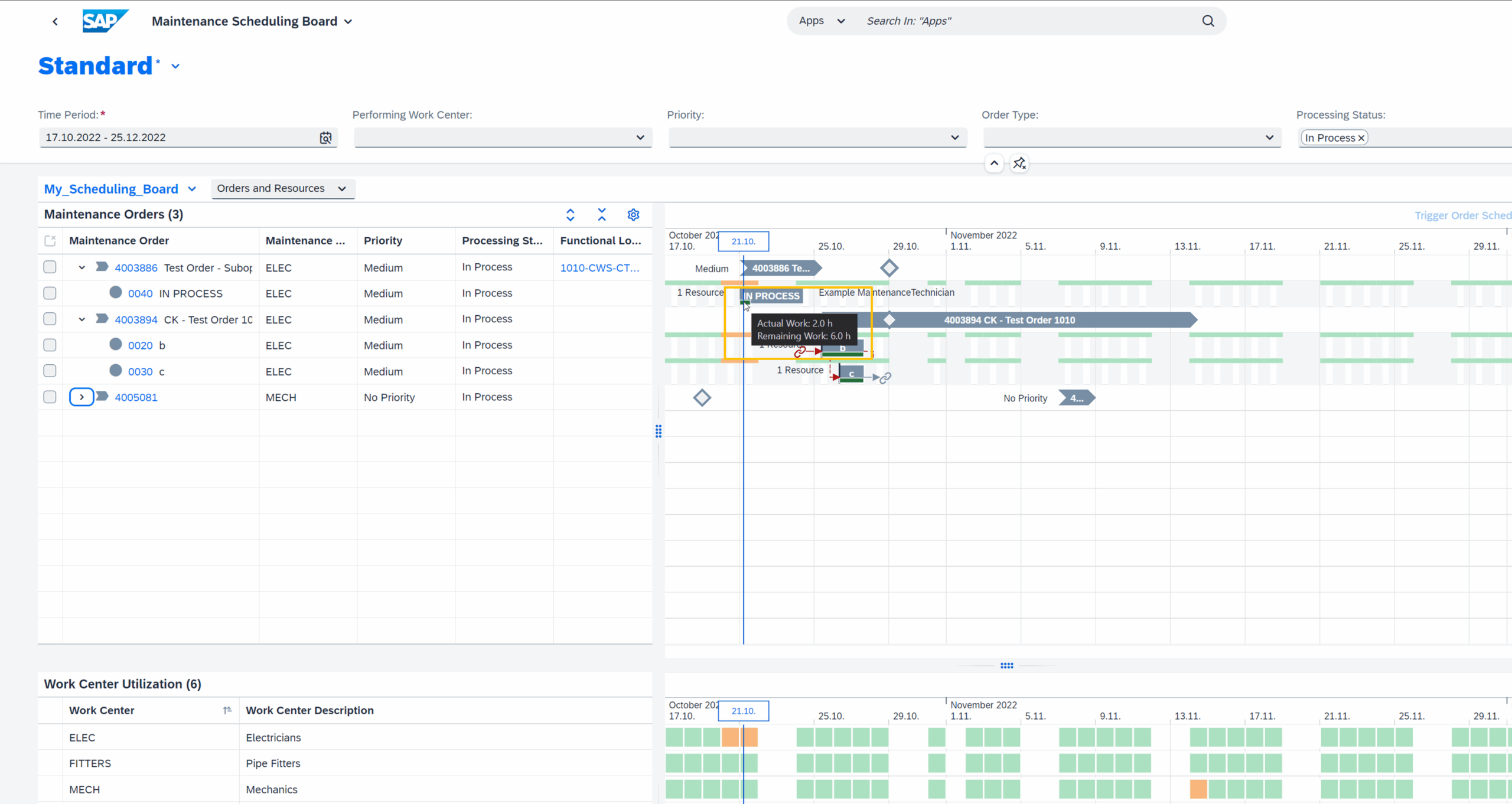

- Resource Management: It helps optimize technician allocation based on their skills, availability, and the urgency of the task. No more overbooking or underutilizing your skilled workforce.

- Reporting and Analytics: This was where the true power of data came alive. The system generates comprehensive reports on asset performance, maintenance costs, downtime, technician efficiency, and much more. This data provides invaluable insights for continuous improvement, allowing us to identify problematic assets, optimize maintenance strategies, and make smarter investment decisions.

In essence, ERP Asset Maintenance Scheduling transforms maintenance from a reactive, isolated function into a proactive, integrated, and data-driven process that contributes directly to the business’s bottom line.