I remember the chaos like it was yesterday, though thankfully, it feels like a lifetime ago. Our small manufacturing business, let’s call it ‘Widgets & More,’ was growing, and with growth came a monstrous pile of paperwork and an even bigger headache. Every morning, I’d walk into the office and see stacks of printed orders, faxes, and handwritten notes. Our small team, bless their hearts, would be hunched over keyboards, painstakingly typing information from one system into another, then printing out shipping labels, then manually updating inventory counts. It was a dance of data entry, and frankly, it was a messy, error-prone tango.

Imagine this: a customer calls, wanting to know about their order. Sarah, our customer service superstar, would have to walk over to accounting to see if the payment went through, then to the warehouse manager to see if the item was picked, then back to her desk to check the shipping carrier’s website. Ten minutes, sometimes more, just to answer a simple question. And if the information she got from one department didn’t match another? Well, that was a whole new adventure in detective work, often ending with me, the owner, getting involved to untangle the mess.

Errors were rampant. We’d ship the wrong color widget, or sometimes, the wrong quantity. An order might get processed twice, leading to duplicate shipments and angry customers. Or worse, an order would get lost in the shuffle entirely, only to be discovered weeks later when an irritated customer called, wondering where their items were. Each mistake cost us money, time, and, most importantly, our reputation. I saw the stress in my team’s eyes. They were working hard, often staying late, but it felt like we were constantly running in place, just trying to keep our heads above water. We were drowning in manual tasks.

Our inventory was a guessing game. The warehouse would ship out 50 blue widgets, but because the system wasn’t updated instantly, our sales team might still sell 20 more blue widgets that didn’t exist, leading to backorders and unhappy customers. We’d run out of popular items unexpectedly, or sit on mountains of slow-moving stock, tying up valuable cash. It was a constant struggle to balance what we had with what we needed, and the manual updates meant we were always a step behind.

The turning point came during our busiest season. We got a huge order from a new, important client. Everything seemed fine on paper, but a few weeks later, the client called, furious. Half their order was missing, and the other half was incorrect. It turned out that a crucial piece of information had been manually mistyped during the transfer from the sales order to the shipping manifest. It was a simple, human error, but it nearly cost us that client and a big chunk of future business. That night, sitting alone in my office, surrounded by stacks of paper, I knew something had to change. We couldn’t keep doing things the old way. This wasn’t sustainable; it wasn’t even smart.

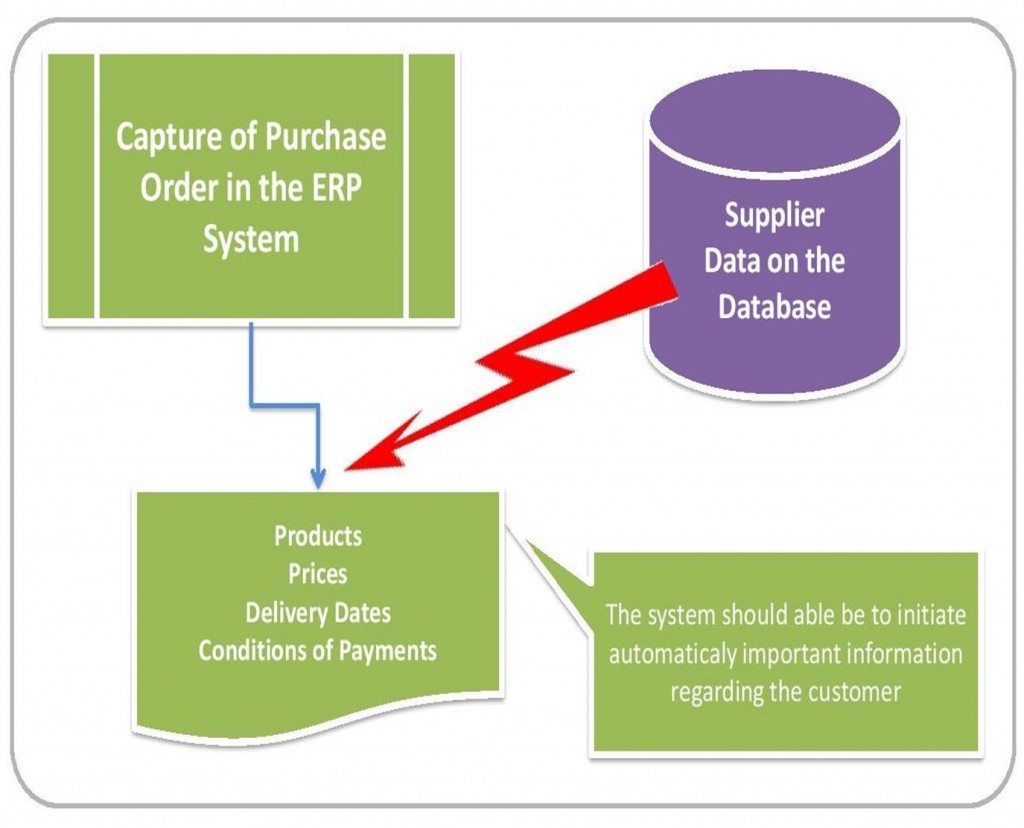

I started looking for solutions. I’d heard whispers of "ERP" – Enterprise Resource Planning – but it always sounded like something only giant corporations used, complex and expensive. But the more I researched, the more I realized that ERP systems, even those designed for smaller businesses like ours, could offer something truly revolutionary: order processing automation. The idea was simple: instead of my team manually moving information from one place to another, a single system would handle it all, automatically.

Initially, I was skeptical. Could one system really manage everything from the moment a customer placed an order to the moment it was delivered and paid for? The thought of changing everything we knew was daunting. The cost was a concern, too. But the thought of another year of chaos, lost orders, and stressed employees was far more terrifying. I reached out to a few ERP providers, explained our situation, and started to understand what this automation truly meant.

Imagine this: a customer places an order on our website or over the phone. Instead of someone manually typing that order into our inventory system, then into our accounting system, then into our shipping system, the ERP would do it all. The moment the order comes in, the system would check inventory availability. If the items are in stock, it would reserve them. It would then generate a pick list for the warehouse. Once picked, it would create the shipping label and even send tracking information to the customer, all without a single person touching a keyboard to re-enter data. When the item ships, the system would automatically update inventory, create an invoice, and even flag it for our accounting team.

This wasn’t just about speeding things up; it was about connecting everything. Inventory, sales, accounting, customer service, shipping – all talking to each other through one central brain. It sounded like magic, but the more I learned, the more I saw the logic and the practical benefits.

The journey to implement ERP order processing automation wasn’t without its bumps. It required careful planning. We had to choose the right ERP system, one that fit our specific needs and budget. We spent weeks cleaning up our existing data – a necessary but tedious task – because as the saying goes, "garbage in, garbage out." Then came the training. My team, used to their old ways, needed to learn a new system. There was a period of adjustment, some frustration, and a lot of questions. But we approached it together, as a team, understanding that this was for the greater good of the business and for their own peace of mind.

And then, slowly but surely, the magic started to happen.

The first noticeable change was the sheer speed. Orders that used to take an hour to manually process, from entry to shipping label generation, now took minutes. The data flowed effortlessly from one stage to the next. When an order came in, the system immediately checked stock. If an item was low, it would alert us, prompting reorders before we ran out. This drastically cut down on backorders and allowed us to better manage our purchasing.

Accuracy skyrocketed. With fewer manual data entries, there were fewer chances for human error. The system would pull customer details directly, ensuring the correct address every time. It would pull product codes, ensuring the right item was shipped. Our error rate plummeted, and with it, the number of customer complaints about incorrect orders. This wasn’t just about saving money; it was about building trust.

Our inventory management went from a chaotic mess to a well-oiled machine. Every sale, every return, every incoming shipment was instantly recorded in the ERP. We had a real-time view of what was in our warehouse. This meant our sales team could confidently tell customers what was available, and I could make smarter decisions about what to order and when. We reduced our overstock of slow-moving items and ensured we always had popular products on hand. This freed up capital and improved our cash flow significantly.

Customer service was transformed. Sarah, our superstar, no longer had to run around the office. With a few clicks, she could see the complete status of any order: when it was placed, if it was paid, where it was in the warehouse, and its tracking number. She could answer customer questions instantly and accurately. Our customers noticed the difference. They felt valued, informed, and cared for. Our customer satisfaction scores improved dramatically, leading to more repeat business and positive reviews.

My team, the very people who were initially hesitant about the change, became its biggest champions. They were no longer spending hours on repetitive, mind-numbing data entry. Instead, they could focus on more meaningful tasks. Sarah could spend more time proactively checking in with important clients. Our warehouse team could focus on efficient picking and packing, rather than deciphering handwritten notes. Our accounting department could process invoices and reconcile payments much faster, freeing them up for financial analysis and strategic planning. The stress level in the office dropped noticeably. There was less frantic rushing, fewer frustrated sighs, and more collaborative problem-solving. People looked happier, more engaged, and less overwhelmed.

As the business owner, the benefits were immense. I gained an unprecedented level of visibility into every aspect of our operations. I could see sales trends, inventory levels, order fulfillment times, and financial performance all from one dashboard. This wasn’t just about knowing what happened yesterday; it was about understanding why it happened and predicting what might happen tomorrow. I could make data-driven decisions about pricing, marketing, and expansion with confidence, rather than relying on gut feelings and outdated reports. This allowed me to steer Widgets & More towards sustainable growth.

The ERP order processing automation wasn’t just a technological upgrade; it was a fundamental shift in how we operated. It moved us from a reactive business, constantly putting out fires, to a proactive one, anticipating needs and seizing opportunities. It gave us the tools to handle more orders with the same, or even fewer, resources, allowing us to scale our operations without having to hire an army of data entry clerks.

For anyone out there still wrestling with manual order processing, with stacks of paper and frustrated teams, I want to tell you my story because I’ve lived through it. I know the pain, the exhaustion, the fear of making a costly mistake. And I’ve also seen the other side. Investing in ERP order processing automation might seem like a big step, a complex undertaking, and yes, it requires an upfront investment of time and money. But the returns, both tangible and intangible, are profound.

It’s not just about saving money on labor or reducing errors, though those are significant. It’s about giving your team back their time and energy, allowing them to contribute to your business in more meaningful ways. It’s about providing your customers with a smooth, reliable experience that builds loyalty. It’s about giving yourself, the business owner, the clarity and control you need to make smart decisions and grow your company.

The old days of chaos are a distant memory for Widgets & More. Now, when I walk into the office, I see a calm, focused team, working efficiently and effectively. The paper piles are gone. The frantic searches for information are gone. What remains is a system that works tirelessly in the background, making sure every order, every customer, and every product is handled with care and precision. And that, truly, is the day our business breathed easy. If you’re at a similar crossroads, wondering if the change is worth it, I can tell you from my own experience: it absolutely is. It’s not just about technology; it’s about building a better, more resilient business.