I remember it like it was yesterday, the sheer chaos that reigned in our operations. Every department seemed to have its own way of doing things, even for the simplest tasks. Orders would get processed differently depending on who was at the keyboard, invoices sometimes went missing in a sea of paper and email chains, and customer service calls often ended with a frustrated sigh from both ends because nobody could quickly pinpoint where a particular issue originated. Our brand-new ERP system, a hefty investment meant to bring order, was instead becoming a digital mirror of our existing disarray. It was a powerful engine, but without a clear map or consistent driving rules, we were just spinning our wheels, albeit at a higher digital speed.

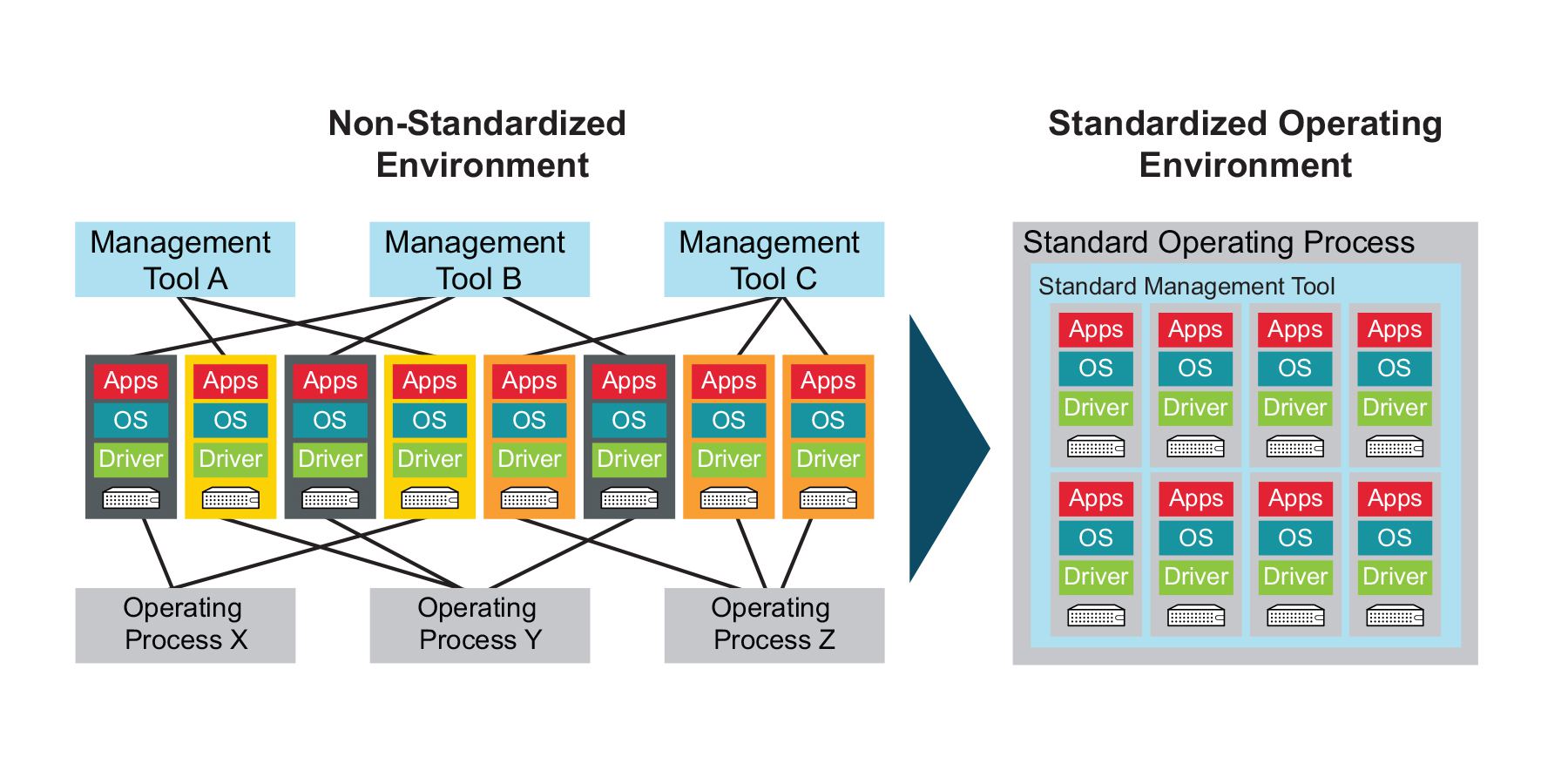

That’s when I stumbled upon the idea, or rather, the absolute necessity, of ERP process standardization. It wasn’t just about using the ERP; it was about defining how we use it, when we use it, and who uses it for what. The goal was simple: make sure everyone followed the same best path, every single time. But how do you take a sprawling organization and get everyone marching to the same beat? That’s where ERP process standardization tools came into the picture, and my journey with them began.

My first encounter with these tools wasn’t with some fancy, expensive software. It was with a whiteboard, a stack of sticky notes, and a determined team. We started by simply drawing out our existing processes – the "as-is" state. For instance, how did an order actually flow from a customer inquiry to delivery? We discovered so many informal steps, detours, and personal shortcuts that were completely invisible on any official flowchart. This initial exercise, though rudimentary, was our first step towards standardization. It highlighted the wild west we were operating in.

Then came the proper introduction to process mapping software. Think of it as a digital whiteboard, but much smarter. We moved from hand-drawn squiggles to structured flowcharts, using universally understood symbols. Tools like these allowed us to visualize complex sequences of tasks, identify bottlenecks, and see where decisions were made. More importantly, they helped us design the "to-be" processes – the standardized, ideal way we wanted things to run. We’d map out, for example, the exact steps for processing a new vendor, ensuring all necessary approvals were captured digitally within the ERP, and that all required data fields were consistently filled. This mapping wasn’t just for IT; it was for every department, providing a clear blueprint that everyone could understand and refer to. It was like finally getting a detailed map of that labyrinth I mentioned earlier.

As we grew more confident, we realized that simply drawing a map wasn’t enough. We needed to ensure people followed it. This led us to explore what I now understand as Business Process Management (BPM) Suites. These weren’t just about drawing; they were about managing the entire lifecycle of a process. Imagine a tool that doesn’t just show you the steps, but also allows you to model those steps, execute them, monitor their performance, and even improve them over time. We could define roles, set deadlines for each task in a process, and even automate notifications if a step was overdue. For instance, when a new employee joined, the onboarding process – from HR paperwork to IT setup and access within the ERP – could be managed through this suite. Each person involved would get their specific tasks, and the system would track progress, ensuring nothing was missed. It was a huge leap from static diagrams to dynamic, living processes.

A natural progression from BPM suites was the adoption of workflow automation tools. While BPM suites help manage the overall process, workflow automation focuses on making specific, repetitive tasks within those processes run automatically. Think about approval flows. Instead of printing a form, walking it to a manager’s desk, waiting for a signature, and then manually entering data into the ERP, an automated workflow tool could handle it all. The request originates in the ERP, triggers an email notification to the manager, who can approve or reject it with a click, and that action automatically updates the ERP record. This eliminated so many manual errors, sped up operations significantly, and freed up our team to focus on more complex, value-added activities. We saw this in action with purchase requisitions, expense report approvals, and even some aspects of customer support ticket routing. The ERP became less of a data entry system and more of an intelligent orchestrator.

Crucially, the ERP system itself holds powerful standardization capabilities. It’s not just external tools; the way you configure your ERP is paramount. We realized that standardizing processes meant standardizing the data and settings within the ERP. This involved meticulous attention to configuration management. We defined standard chart of accounts, standardized naming conventions for products and services, consistent customer and vendor master data entry rules, and uniform user roles and permissions. If everyone is entering a customer’s address in a slightly different format, or if product codes are inconsistent, your reports become meaningless, and your processes break down. The ERP’s configuration tools, though sometimes a bit technical to set up, were fundamental in enforcing consistency at the very core of our data. It meant that a new sales order, no matter who entered it, would follow the exact same data structure, linking to the correct inventory and accounting entries automatically. This internal standardization within the ERP was the bedrock upon which all other process improvements were built.

But what good are perfectly standardized processes and powerful tools if no one knows how to use them, or worse, if they resist using them? This brought us to the often-overlooked but absolutely critical aspect: training and documentation platforms. We used these tools to create a central repository of our standardized processes, complete with step-by-step guides, screenshots of the ERP interface, and even short video tutorials. Whenever a process was updated (and they always are!), everyone had immediate access to the latest version. This wasn’t just a static manual; it was an interactive learning environment. We developed quizzes to ensure understanding and forums for users to ask questions and share best practices. It meant that new hires could quickly get up to speed, and existing employees could always refresh their knowledge. The investment in making sure our team understood and could easily follow the standardized processes was just as important as the tools themselves.

Finally, my journey taught me that standardization isn’t a destination; it’s a continuous journey. Processes evolve, business needs change, and the ERP system itself gets updated. This is where change management tools and frameworks became invaluable. It wasn’t about a piece of software, but rather a structured approach to introducing and sustaining changes. We learned how to communicate the "why" behind changes, how to involve key users in the design of new processes, and how to address resistance proactively. For example, when we introduced a new automated approval workflow, we didn’t just roll it out. We held workshops, explained the benefits (less paperwork, faster approvals for them), and provided ample support during the transition. It was about making people feel like part of the solution, not just recipients of new rules. Tools in this space might include project management software to track change initiatives, or survey tools to gather feedback on new processes.

Looking back, the benefits we reaped from embracing ERP process standardization tools were profound. Our operations became significantly more efficient. Tasks that once took hours, fraught with manual handoffs and potential errors, were completed in minutes. We saw a dramatic reduction in operational costs due to less rework and fewer mistakes. Data accuracy improved across the board, which, in turn, led to better, more reliable reporting. This meant our leadership could make faster, more informed decisions, confident that the numbers reflected reality. Our customer satisfaction soared because service was more consistent and predictable. We were also much better positioned for growth; scaling our operations became easier because we had repeatable, documented processes that new teams could quickly adopt. And, in today’s regulatory environment, having clearly defined and auditable processes meant we were better equipped to meet compliance requirements.

Of course, the journey wasn’t without its challenges. The initial setup of these tools and the redesign of processes required significant time and resources. There was often resistance from team members who were comfortable with their old ways and saw standardization as a loss of autonomy or an imposition. Choosing the right tools from a crowded market was also a puzzle, requiring careful consideration of our specific needs, budget, and integration capabilities with our existing ERP. And perhaps the biggest challenge was the understanding that this was not a one-time project, but an ongoing commitment to continuous improvement. Processes always need tweaking, updating, and refining.

For anyone just starting to look at ERP process standardization, my advice is simple: start small. Don’t try to standardize everything at once. Pick a critical, problematic process and focus your efforts there. Get buy-in from the people who actually perform the tasks; their insights are invaluable. Don’t underestimate the human element; successful standardization hinges on user adoption and a culture that embraces change and continuous improvement. And remember, the tools are just enablers. They provide the framework and the capabilities, but it’s the people, the clear vision, and the commitment to consistency that truly bring about transformational change.

My journey with ERP process standardization tools taught me that an ERP system, no matter how sophisticated, is only as good as the processes it supports. By leveraging these tools, we didn’t just install a new system; we redefined how we worked, transforming chaos into order, and paving the way for a more efficient, predictable, and ultimately, successful future. It was a journey of understanding, implementation, and continuous learning, and one that I wholeheartedly recommend to any organization grappling with the complexities of modern business operations.