I remember it like it was yesterday, the sheer pandemonium that used to be our manufacturing floor. Papers piled high, whiteboards crammed with scribbled schedules that changed hourly, foremen shouting updates across the din of machinery, and the constant scramble to find a specific part or verify an order. It was a dance, alright, but a chaotic, exhausting one, riddled with missteps and missed deadlines. Our little manufacturing company, built on passion and hard work, was hitting a wall. We were growing, which was fantastic, but the complexity of managing everything manually was crushing us. We needed a change, a big one, and that’s when we started hearing whispers about something called ERP, specifically how it could revolutionize manufacturing workflow automation.

At first, the idea felt overwhelming. ERP, or Enterprise Resource Planning, sounded like a giant, intimidating beast of software. Automation? We pictured robots taking over, or worse, a rigid system that would stifle our adaptability. But the truth was, our existing manual processes were already stifling us. Errors were common, leading to costly rework and wasted materials. Communication breakdowns meant production delays. Inventory was either overflowing with unnecessary stock or critically short on essential components. We lacked a clear, real-time picture of anything, from incoming orders to outgoing shipments. We were flying blind, relying on gut feelings and frantic phone calls.

So, we took the plunge. We decided to explore how an ERP system could specifically automate our manufacturing workflows. It wasn’t about replacing people, we quickly learned, but about empowering them, giving them the tools to work smarter, not just harder. The journey was transformative, and I want to share what we discovered, piece by piece, as we watched our chaotic manufacturing world slowly, beautifully, fall into a rhythm of seamless automation.

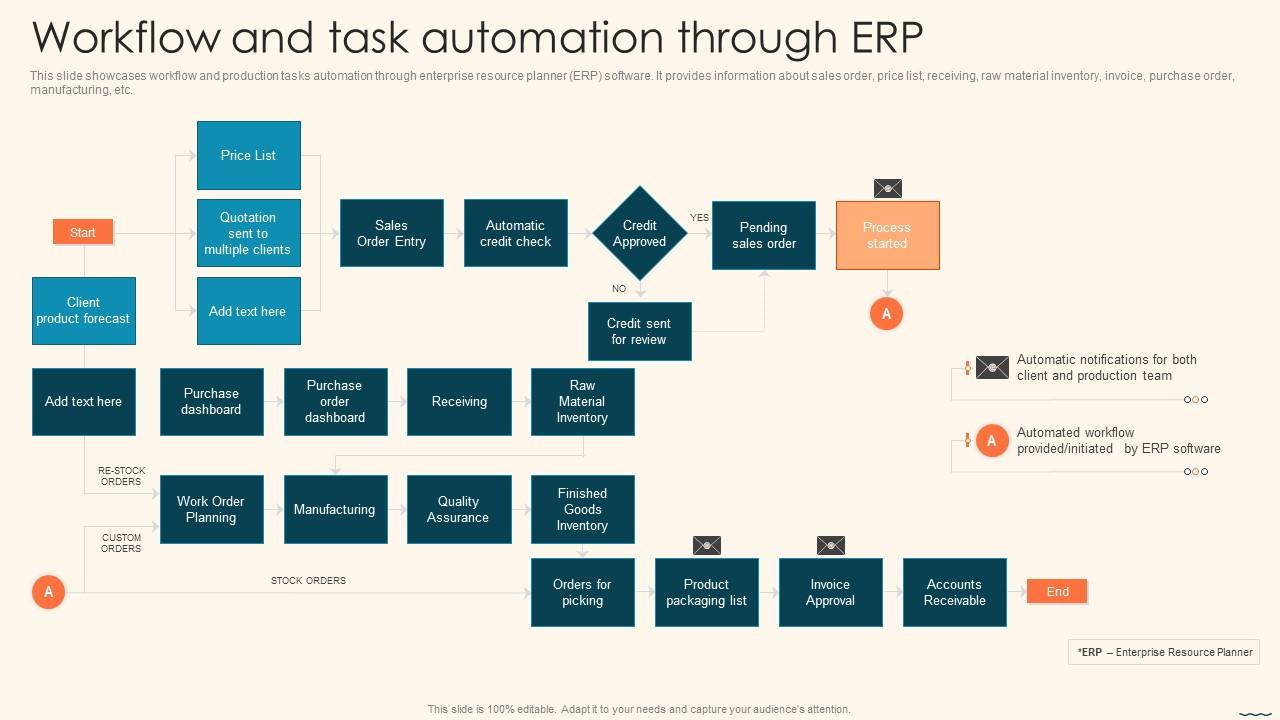

Our first big hurdle was Order Management. Before ERP, a customer order would come in, usually via email or phone. Someone in sales would manually enter it into a spreadsheet, then print it out and walk it over to production planning. Pricing was often a quick lookup, sometimes leading to inconsistencies. Special requests would get lost in translation. With ERP, it was like magic. Orders now flow directly into the system. As soon as an order is confirmed, the ERP checks stock availability, verifies pricing based on pre-set rules, and even flags potential issues like missing customer details. The system creates a digital sales order, instantly visible to everyone who needs to see it – sales, production, inventory, and even finance. This immediate, accurate data entry eliminated a huge source of errors and kickstarted the entire production process with precision. No more misplaced paper orders, no more manual re-entry errors.

Once an order was in, the next challenge was translating it into a tangible product. This meant dealing with Bill of Materials (BOM) and Routing. Our old BOMs were often outdated spreadsheets or even handwritten lists, tucked away in dusty folders. If a product design changed, updating all relevant BOMs was a nightmare, and often, old versions would still get used, leading to incorrect parts being ordered or assembled. Routing – the sequence of operations required to make a product – was equally haphazard, based on tribal knowledge rather than standardized processes. ERP brought an incredible level of discipline here. Every product now has a master BOM within the system, detailing every component, sub-assembly, and raw material required, along with their quantities. When a design changes, we update it once in the ERP, and every related order, every production run, instantly uses the correct, most current BOM. The same goes for routing. The system defines the exact steps, the machines involved, the estimated time for each operation. This standardization ensures consistency, quality, and drastically reduces errors stemming from using wrong materials or following incorrect procedures. It was like having a meticulously organized blueprint for every single item we produced.

Then came Inventory Management, a beast that used to haunt our nights. We had shelves overflowing with parts we didn’t need and critical components perpetually out of stock. Manual stock counts were infrequent and inaccurate. Forecasting demand was more like guessing games. With ERP, we moved from reactive to proactive. The system provides real-time visibility into every single item in our warehouse – how much we have, where it’s located, when it arrived, and even its lot number for traceability. As soon as a component is consumed in production or a finished product is shipped, the inventory count updates automatically. But it goes beyond simple counting. ERP uses historical sales data, current orders, and even external market trends to generate intelligent demand forecasts. This allows us to optimize our ordering, reducing excess stock (and the associated holding costs) while ensuring we always have enough critical components to avoid production halts. We started seeing less waste, fewer urgent, expensive rush orders, and a much healthier cash flow. It was like finally having x-ray vision into our warehouse, knowing exactly what we had and what we needed at all times.

With accurate BOMs and real-time inventory, we could finally tackle Production Planning and Scheduling. This was perhaps the most visibly transformed area. Gone were the wall-sized whiteboards, filled with erased and rewritten schedules. Our old system was rigid; if one machine broke down, the entire schedule would unravel, leading to delays and frustrated workers. ERP changed all of that. Based on confirmed orders, available materials, machine capacity, and even employee availability, the system dynamically generates optimized production schedules. If a machine goes down, the ERP can quickly re-sequence jobs to other available machines or adjust timelines, notifying all relevant departments automatically. It considers bottlenecks, lead times, and priorities to create a smooth flow. We could run "what-if" scenarios, seeing the impact of a large rush order or a machine maintenance shutdown before it even happened. This agility was revolutionary. Our production floor went from being a place of constant firefighting to one of predictable, efficient progress. It was like having a brilliant chess master constantly optimizing our production moves.

The changes weren’t just in planning; they extended right onto the Shop Floor Control. This was where the real rubber met the road. Before ERP, tracking progress was a manual effort – workers filling out paper travelers, foremen tallying completion rates. This meant data was always old by the time it was analyzed. With ERP integration, our machines started talking to the system. Data on production quantities, machine uptime, and even quality checks were captured in real-time, often automatically through sensors or simple barcode scans by operators. This meant that management had an instantaneous view of how every job was progressing. If a job was falling behind schedule, we knew immediately, not hours or days later. This allowed us to intervene quickly, troubleshoot issues, and keep production on track. Operators could access their work instructions, BOMs, and routing details directly from terminals on the shop floor, ensuring they always had the most current information. It was like installing a nervous system throughout our factory, providing instant feedback from every extremity.

Quality Control also saw a massive improvement. Before, quality checks were often isolated, recorded on separate forms, and hard to link back to specific batches or operators. If a quality issue arose, tracing its origin was a detective mission. ERP integrated quality checks directly into the production workflow. At specific points in the routing, operators are prompted to perform checks and record results directly into the system. If a parameter falls outside tolerance, the system can immediately flag it, preventing further processing of defective parts. More importantly, every product, every component, every step in its journey is now traceable. If a customer reports a defect, we can pinpoint the exact batch, the materials used, the machines involved, and even the operators on duty at that time. This level of traceability isn’t just about compliance; it’s about continuous improvement. We could identify patterns in defects, understand their root causes, and implement preventive measures. It was like having an unwavering guardian ensuring the integrity of every product we made.

Beyond the immediate production cycle, ERP automation also touched areas like Maintenance and Supply Chain Management. For maintenance, the system tracked machine usage, scheduling preventive maintenance based on actual run time rather than arbitrary calendars. This reduced unexpected breakdowns, extending machine life and minimizing production interruptions. For our supply chain, ERP streamlined procurement. When inventory levels dropped below a certain point, the system could automatically generate purchase requisitions or even orders, sending them to pre-approved vendors. We could track vendor performance, negotiate better terms based on historical data, and ensure a steady flow of materials without manual oversight. This integrated approach made our entire operation more resilient and responsive to market changes.

And, of course, the financial implications were profound. Financial Integration is a core strength of ERP. Every transaction – an order received, materials consumed, a product shipped – has a financial impact that is automatically recorded. This means real-time costing for every product, accurate profit and loss statements, and granular financial reporting without the need for endless manual data entry and reconciliation between disparate systems. We could see the true cost of production, identify areas of inefficiency, and make data-driven decisions about pricing and investment. It was like having an incredibly diligent accountant keeping track of every penny, every moment.

The biggest surprise for us wasn’t just the operational efficiency gains, though those were substantial. It was the shift in our company culture. The frustration of constant errors and manual firefighting was replaced by a sense of control and clarity. Employees, initially wary, became champions of the system as they saw how it simplified their work, reduced stress, and allowed them to focus on value-added tasks rather than administrative drudgery. Decisions were no longer made in silos but based on a shared, accurate, and real-time view of the entire business.

Implementing ERP wasn’t without its challenges, mind you. It required a significant investment of time and resources, not just financially but in terms of training and process re-evaluation. We had to confront old habits, challenge existing workflows, and embrace new ways of working. Data migration was a massive undertaking, and there were moments of frustration when things didn’t work exactly as expected. But through careful planning, dedicated training, and a willingness to adapt, we overcame these hurdles. We learned that ERP isn’t a magic bullet; it’s a powerful tool that requires commitment and continuous refinement to unlock its full potential.

Looking back, the transformation was nothing short of revolutionary for our manufacturing company. We moved from a state of reactive chaos to one of proactive, predictable, and remarkably efficient production. Our lead times shrunk, our product quality improved, and our operational costs decreased significantly. We gained an unparalleled level of visibility into every corner of our business, enabling us to make faster, smarter decisions. We became more agile, more competitive, and frankly, a much more enjoyable place to work.

For any manufacturing business grappling with inefficiency, errors, and a lack of control, my experience tells me that ERP manufacturing workflow automation isn’t just an option; it’s an imperative. It’s not about making machines run faster in isolation, but about orchestrating the entire symphony of your operations, ensuring every instrument plays in harmony, creating a seamless, powerful, and ultimately, profitable performance. It was a journey from the messy, manual past into a future where technology truly served to amplify human ingenuity, making our manufacturing dreams a tangible reality.