I remember a time, not so long ago, when our company’s ERP system felt less like a sophisticated business tool and more like a stubborn, overgrown garden. We’d invested a hefty sum, hoping for streamlined operations, better data, and a clearer picture of our business. What we got, initially, was a tangled mess of manual workarounds, baffling data discrepancies, and a collective sigh of frustration whenever someone mentioned "the ERP." It wasn’t the system’s fault entirely; it was how we were using it, or rather, not using it, and the processes we’d unwittingly built around it that were the real culprits.

We had all the data, but it was like trying to find a specific needle in a haystack the size of a mountain, blindfolded. Reports took days to compile, often requiring data from three different departments to be manually reconciled in spreadsheets. Approvals were a paper chase, literally, with documents sometimes sitting on someone’s desk for a week before moving to the next. Our customer service team struggled to give quick answers because accessing a complete customer history meant jumping through multiple screens and waiting for slow queries. Production schedules were constantly shifting, leading to missed deadlines and unhappy clients. It was clear we were bleeding time, money, and morale, and our expensive ERP, instead of being the solution, felt like it was just highlighting the problems.

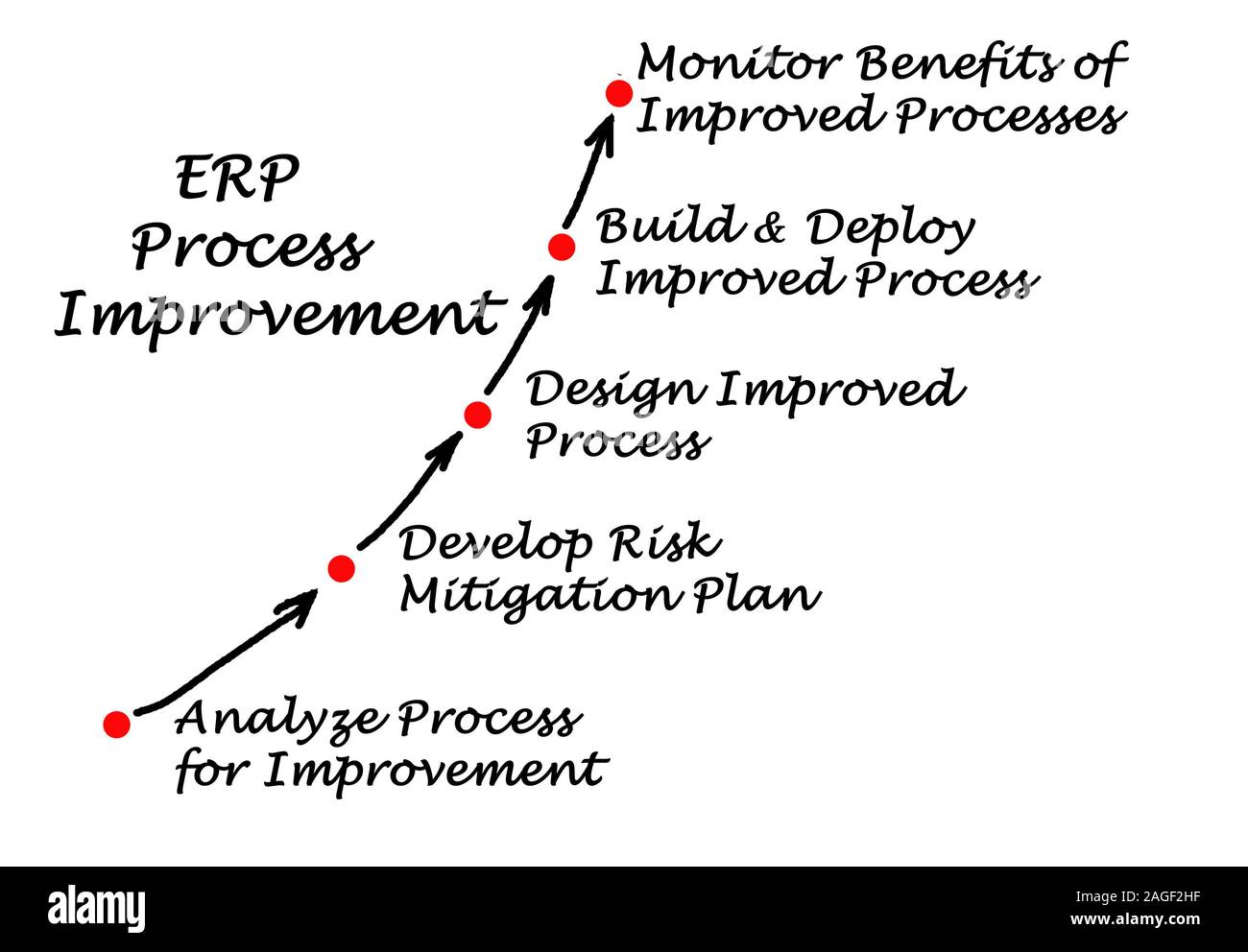

This wasn’t a unique situation, I learned. Many companies implement an ERP with high hopes, only to find their existing, often inefficient, processes get digitally replicated, or even amplified, within the new system. It’s like paving a superhighway over a bumpy, winding dirt road without bothering to straighten it out first. You can drive faster, but you’re still taking all the detours. That’s when I realized we didn’t just need an ERP; we needed to fix how we worked with the ERP. We needed ERP process improvement tools.

The idea of "process improvement" might sound a bit daunting, like something only a team of highly paid consultants could tackle. But I discovered it’s really about stepping back, looking at how things get done, and finding smarter, faster, and more reliable ways to achieve the same results. For us, it started with a simple question: "What exactly is happening here?"

Our first foray into understanding our tangled processes began with something remarkably low-tech, yet incredibly powerful: Process Mapping Tools. Think of it as drawing a treasure map, but instead of gold, you’re looking for bottlenecks, redundancies, and manual steps. We started with a simple whiteboard and sticky notes. For a specific process, like "order-to-cash," we’d gather everyone involved – sales, operations, finance – and literally map out every single step, every decision point, every handoff. It was messy, often involving heated discussions about "who does what," but for the first time, we had a visual representation of our current state.

Soon, we moved from whiteboards to more sophisticated digital tools like Lucidchart and Microsoft Visio. These tools allowed us to create professional-looking flowcharts, complete with standardized symbols for different actions, decisions, and data flows. The beauty of these tools wasn’t just in making pretty diagrams; it was in the clarity they provided. When you can see the process, it becomes much easier to identify where things go wrong. We found steps that were duplicated, unnecessary approval loops, and points where data was manually re-entered from one system to another, leading to errors. Mapping wasn’t about fixing; it was about seeing the problem clearly, like getting an X-ray before surgery. It was our first big step out of the chaos.

Once we had a clearer picture of our existing processes, the next challenge was figuring out where the real pain points were. This is where a truly transformative set of tools came into play: Process Mining Tools. Imagine having a detective who can go through all the digital footprints left by your ERP system – every click, every transaction, every status change – and reconstruct the actual journey of your processes. That’s what process mining does. Tools like Celonis or UiPath Process Mining (formerly ProcessGold) connect directly to your ERP data and automatically discover the actual workflows.

It was an eye-opener. Our painstakingly mapped "ideal" process often looked quite different from the "real" process revealed by process mining. We discovered hidden variations, rework loops we never knew existed, and bottlenecks that were much worse than we’d imagined. For example, our order fulfillment process, which we thought was fairly straightforward, had dozens of variations depending on the product, customer, or even the sales representative. Process mining showed us exactly which variations were causing delays, which customers were affected most, and where resources were being wasted. It gave us quantifiable data – average cycle times, deviation rates, re-work percentages – that we could use to prioritize our improvement efforts. It was like finally getting an MRI after relying on just an X-ray. We saw the details, the deviations, and the real reasons for the pain.

With a clear understanding of our existing processes (thanks to mapping) and data-driven insights into their actual performance (thanks to process mining), we were ready to start redesigning. This is where the world of Business Process Management (BPM) Suites became incredibly valuable. A BPM suite isn’t just a tool; it’s a platform that helps you design, execute, monitor, and optimize your business processes. Think of platforms like Appian, Pega, or Oracle BPM.

These suites allowed us to move beyond just drawing pretty pictures of our processes. We could actually build our improved workflows within the system. This meant digitizing forms, automating approvals based on predefined rules, and ensuring that tasks automatically moved from one person or department to the next. For our cumbersome invoice approval process, for instance, we designed a workflow in our BPM suite that automatically routed invoices to the correct approver based on amount and department, sent reminders, and escalated if an approval was delayed. This dramatically cut down approval times from days to hours, freeing up our finance team to focus on more strategic tasks. It was like moving from a manual blueprint to an automated factory floor.

While BPM suites handle the orchestration of complex end-to-end processes, we still had many smaller, repetitive tasks that were eating up valuable employee time. This is where Robotic Process Automation (RPA) stepped in. RPA tools, like UiPath, Automation Anywhere, or Blue Prism, are essentially software robots that can mimic human actions when interacting with digital systems. They can open applications, log in, copy and paste data, move files, and even generate reports.

We used RPA to automate tasks like data entry from customer emails into our ERP, reconciling purchase orders with invoices, and generating daily sales reports. It wasn’t about replacing people; it was about freeing them from the mundane, repetitive work that nobody enjoyed anyway. Our customer service team, for example, used to spend hours manually updating customer records after a service request was completed. An RPA bot now handles this in minutes, allowing our team to focus on direct customer interaction and problem-solving. It’s like having a tireless digital assistant for every employee, handling all the boring, repetitive chores. The impact on employee morale was incredible; they felt valued for their problem-solving skills, not their data-entry speed.

Another powerful category of tools that emerged as we progressed were Low-Code/No-Code Platforms. These platforms, such as Microsoft Power Apps, Mendix, or OutSystems, empower business users, not just professional developers, to build applications and automate workflows. They use visual interfaces with drag-and-drop functionality, significantly reducing the need for complex coding.

We found these platforms incredibly useful for creating custom applications that filled gaps in our ERP’s functionality or streamlined specific departmental processes that weren’t complex enough for a full BPM suite. For example, our field service team needed a simple mobile app to quickly log service calls and update job statuses directly into the ERP. Building a full-fledged app would have taken months and significant developer resources. With a low-code platform, a technically inclined business analyst built a functional app in a matter of weeks. It democratized innovation, allowing those closest to the problems to build their own solutions, quickly and efficiently, without waiting in a long IT queue.

Of course, improving processes isn’t a one-time event. It’s a continuous journey. To ensure our improvements were sticking and to identify new areas for optimization, we leaned heavily on Data Analytics and Business Intelligence (BI) Tools. Tools like Tableau, Power BI, or Qlik Sense allowed us to create interactive dashboards and reports that visualized key performance indicators (KPIs) related to our processes.

We tracked things like average order processing time, invoice approval rates, inventory turnover, and customer satisfaction scores. By monitoring these metrics in real-time, we could quickly spot if a newly improved process started to backslide or if a new bottleneck emerged. This continuous feedback loop was crucial. It meant we weren’t just guessing if our improvements were working; we had the data to prove it, or to show us where further adjustments were needed. It was like having a constant pulse check on our operational health, allowing us to make data-driven decisions rather than relying on gut feelings.

Throughout this entire journey, one thing became abundantly clear: tools alone aren’t enough. The most sophisticated software in the world won’t succeed if people don’t embrace it. This is where Change Management Frameworks and Tools become vital. While not software in themselves, methodologies like Kotter’s 8-Step Process for Leading Change or the ADKAR Model (Awareness, Desire, Knowledge, Ability, Reinforcement) provided us with a roadmap for guiding our teams through the changes.

We learned the hard way that simply announcing a new process or tool wasn’t enough. We had to explain the "why" – why the change was necessary and how it would benefit individuals and the company. We invested in training, created champions within departments, and celebrated small wins. We also made sure to listen to feedback and adjust where necessary. It was about bringing people along on the journey, not dragging them. Without a focus on the human element, even the best ERP process improvement tools would have gathered digital dust.

Looking back, our journey from chaos to clarity wasn’t a straight line. There were bumps, detours, and moments of doubt. But by systematically applying these ERP process improvement tools, we transformed our operations. Our order fulfillment process is now lean and predictable, our finance team closes books faster, and our customer service is more responsive. Data, once a source of frustration, is now a powerful asset, providing insights that drive strategic decisions.

For anyone feeling overwhelmed by their ERP system, my advice is this:

- Don’t panic, but don’t ignore the problem. The pain you feel is real, and there are solutions.

- Start with understanding. Before you buy any tool, use process mapping to visualize your current state. You can even start with sticky notes and a whiteboard.

- Get data-driven. Once you have an idea of your processes, consider process mining to uncover the actual workflows and identify quantifiable bottlenecks. It’s a game-changer.

- Automate wisely. Look for repetitive, rules-based tasks that can be handled by RPA, freeing your team for more valuable work.

- Build strategically. For larger process overhauls, BPM suites offer robust platforms. For smaller, specific needs, low-code/no-code platforms can be incredibly empowering.

- Measure everything. Use BI tools to monitor your processes continuously. What gets measured gets managed and improved.

- Bring your people with you. Change is hard. Invest in communication, training, and support. The best tools are useless if your team isn’t on board.