From Chaos to Clarity: My Journey with ERP End-To-End Supply Chain

Let’s start at the beginning, shall we? My name isn’t important for this tale, but my experience running a growing manufacturing and distribution company certainly is. For years, we operated like many businesses do: sales had their system, production had their whiteboards and custom software, inventory was managed in a mix of spreadsheets and gut feelings, and accounting had their own separate world. We were busy, we were making money, but honestly? We were constantly on the edge of disaster.

The Fragmented Reality: Our Pre-ERP Days

Imagine trying to bake a complex cake with five different chefs, each with their own recipe, their own ingredients list, and their own oven, all working in separate kitchens. That’s what our supply chain felt like.

- Procurement (buying raw materials): Our purchasing manager would place orders based on historical data and frantic calls from production. Sometimes we’d have too much of one component, gathering dust and tying up cash. Other times, we’d have none, bringing production to a screeching halt. We called these "stockouts," and they were our recurring nightmare.

- Production: Our factory floor was a hive of activity, but planning was reactive. When a big order came in, we’d scramble for materials. When materials finally arrived, we’d find bottlenecks because another part wasn’t ready. We constantly missed delivery dates.

- Inventory Management: This was perhaps the biggest black hole. We knew, roughly, what we had. But exactly how much? Where was it? Was it allocated to an order? Was it about to expire? These questions often led to manual counts, frantic searches, and even more frantic re-orders for items we already had but couldn’t find.

- Logistics & Distribution: Getting finished products to customers involved more phone calls, more spreadsheets, and hoping the delivery truck left on time with the right shipment. Customer inquiries about their order status were met with a shrug and a promise to "check the system" (which usually meant calling three different departments).

- Sales & Customer Service: Our sales team worked hard, but couldn’t promise accurate delivery dates. Our customer service reps spent half their day tracking down information, leading to frustrated customers and an even more frustrated team.

The common thread? A complete lack of visibility across the entire operation. It was like driving a car blindfolded, occasionally peeking through a tiny crack. We were reactive, not proactive. We were losing money to waste, inefficiency, and lost sales opportunities. My nights were filled with worrying about unexpected costs, customer complaints, and looming deadlines.

The "Aha!" Moment: Why We Needed Change

One day, after a particularly painful incident involving a major customer order being delayed because of a missing component we thought we had in stock, I realized something profound. It wasn’t just one problem – it was a systemic issue. All our departments were islands, disconnected and unable to share crucial information in real-time. We needed a bridge, a central nervous system for our entire business.

That’s when I first seriously explored the concept of ERP End-To-End Supply Chain Management.

What Exactly is ERP End-To-End Supply Chain?

Let’s break it down simply for beginners.

ERP stands for Enterprise Resource Planning. Think of it as a giant, intelligent brain for your entire company. Instead of separate systems for sales, finance, inventory, and production, an ERP system brings all that information together into one single, unified database. When something happens in one department – say, a sales order is placed – everyone else who needs to know instantly sees that information updated in real-time.

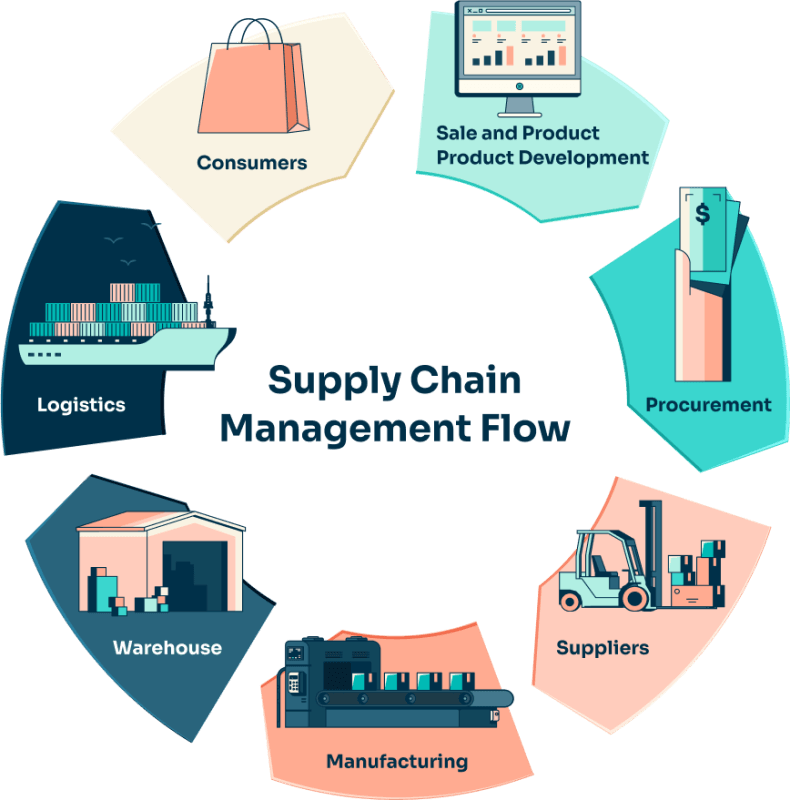

Now, add "End-To-End Supply Chain" to that. This means the ERP system isn’t just managing your internal operations. It’s designed to give you visibility and control over every step of your product’s journey, from the moment raw materials are sourced from your suppliers, through your manufacturing process, all the way to the final delivery to your customer, and even after-sales service.

Imagine our cake analogy again. With an ERP End-To-End Supply Chain system, all five chefs are now working in the same kitchen, using the same recipe, sharing the same ingredient list, and constantly communicating. They know exactly what’s needed, when it’s needed, and who’s doing what. That’s the power!

Key Components of ERP End-To-End Supply Chain (The Modules that Changed Our Lives):

- Procurement & Sourcing: This module became our eyes and ears for everything we bought. It helped us:

- Manage vendors and supplier relationships.

- Automate purchase order creation based on demand.

- Track incoming shipments and predicted arrival times.

- Negotiate better prices with data, not just guesswork.

- Result: No more unexpected material shortages or overstocking.