The Unsung Hero of My Business: Unveiling the Power of ERP Material Requirement Planning (MRP)

I remember a time when my business felt like a perfectly orchestrated ballet of chaos. Every day was a frantic scramble, a delicate dance between impending stockouts and mountains of dust-collecting, overstocked inventory. My heart would sink with every unexpected rush order, and the phrase "we don’t have that part!" echoed more often than I’d like to admit. If you’ve ever run a manufacturing or assembly business, you know the feeling – that constant tightrope walk between having too much and not enough.

Then, I discovered the unsung hero that transformed my operations: ERP Material Requirement Planning (MRP). It wasn’t a magic wand, but it felt pretty close. Let me tell you my story.

A Glimpse into My Past Life: The Spreadsheet Saga and the Sinking Feeling

Before MRP, my inventory management strategy was a Frankenstein’s monster of spreadsheets, gut feelings, and last-minute heroics. We built custom furniture, and each piece required a myriad of components: specific wood types, screws, hinges, fabric, foam, and specialized hardware.

Here’s what my daily routine often looked like:

- The "Oops, We’re Out!" Moment: A production line would grind to a halt because we suddenly realized we were short on a specific type of hinge for a big custom order. Cue the frantic phone calls to suppliers, expedited shipping fees, and angry customers wondering about delays.

- The "Why Do We Have So Much Of This?" Dilemma: On the flip side, I’d walk through the warehouse and see pallets of obscure fabric or a particular screw type that we bought in bulk for a project that was completed months ago. That wasn’t just physical space being wasted; it was cash tied up, gathering dust, losing value.

- The Forecasting Fiasco: We tried to forecast demand, but it was like predicting the weather with a blindfold on. Sales data was in one system, production schedules in another, and supplier lead times were often just a guess. The disconnect was palpable.

- Manual Labor, Human Error: Every order meant someone manually checking inventory, creating purchase orders, and updating multiple spreadsheets. It was tedious, prone to errors, and consumed hours that could have been spent on growth and innovation.

My team was stressed, our cash flow was erratic, and frankly, I was exhausted. I knew there had to be a better way to manage our materials, to ensure we had what we needed, when we needed it, without suffocating under excess stock.

Then Came the Lightbulb Moment: Understanding Material Requirement Planning (MRP)

I started researching solutions, and that’s when I stumbled upon the concept of Material Requirement Planning (MRP). At first, it sounded like complex jargon, but as I dug deeper, it clicked. It wasn’t just about knowing what you needed; it was about knowing when you needed it, and how much.

Think of it like this: If you’re planning a big dinner party, you don’t just randomly buy ingredients. You look at your recipes (the Bill of Materials), check your fridge (current inventory), note how many guests are coming (Master Production Schedule), and then decide what to buy and when to buy it so everything is fresh and ready on time.

MRP, in essence, does that for a manufacturing business, but on a grand, interconnected scale.

What Exactly is MRP? A Jargon-Free Explanation

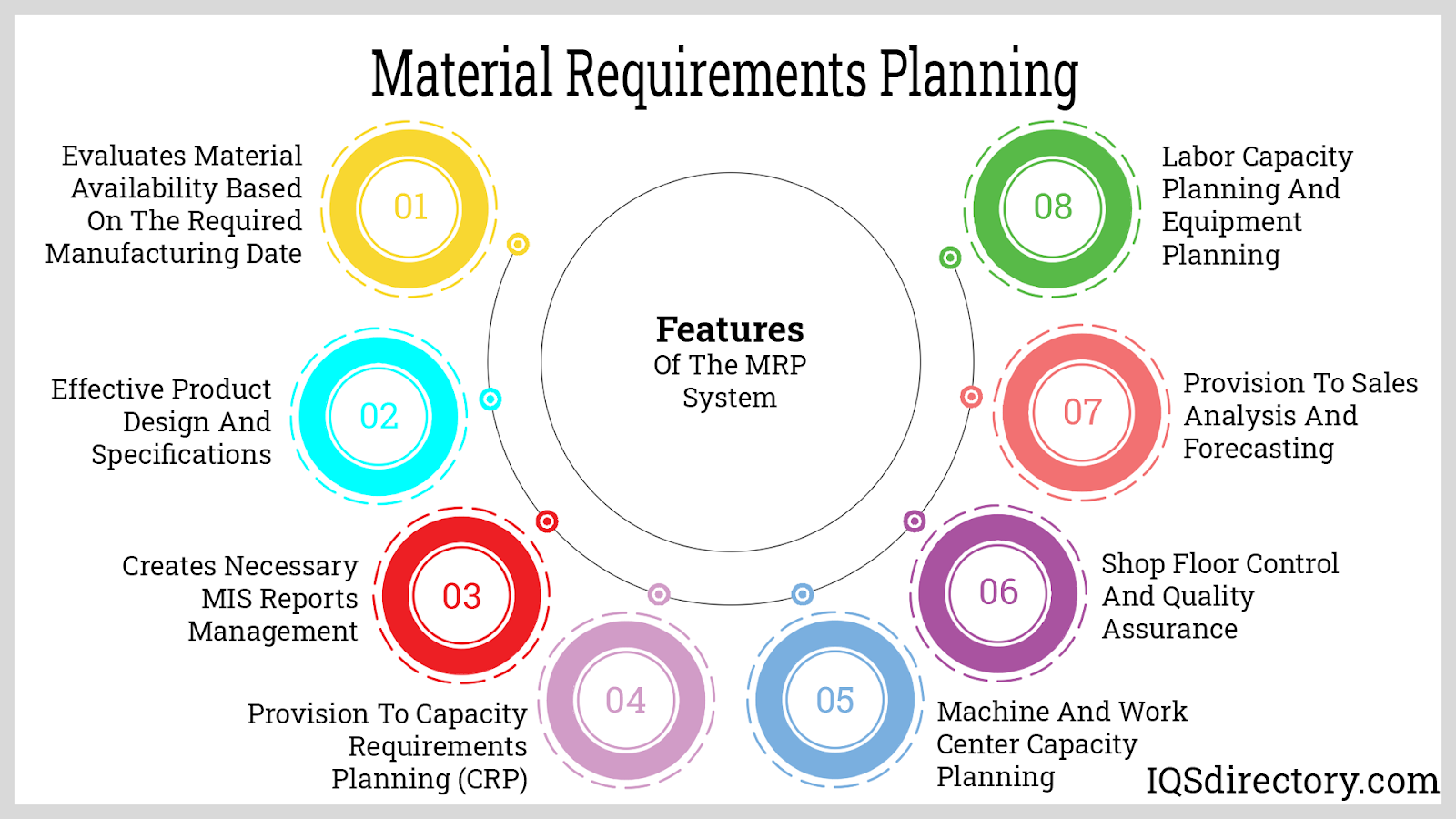

At its core, Material Requirement Planning (MRP) is a system used in manufacturing to plan and control inventory and production. Its primary goal is to ensure that:

- Materials are available when needed for production and customer delivery.

- Inventory levels are kept to a minimum without compromising production.

- Production and purchasing activities are planned effectively.

It’s about having the right parts, in the right quantity, at the right time, at the lowest possible cost. Simple, right? But the magic is in how it achieves this.

Deconstructing the Magic: How MRP Actually Works (Simplified for Beginners)

MRP isn’t a standalone tool; it’s a powerful module typically integrated within a larger Enterprise Resource Planning (ERP) system. This integration is crucial, as it pulls data from across your business to make intelligent decisions.

Here’s a simplified breakdown of how it works its magic: