I remember a time, not so long ago, when getting anything purchased at work felt like navigating a dense jungle armed with nothing but a crumpled map and a faint hope. If you needed a new monitor, a specific software license, or even just a bulk order of coffee for the breakroom, it kicked off a ritual that was more endurance test than efficient process. You’d scribble down your request on a paper form – sometimes a pre-printed one, sometimes just a blank sheet of paper if you were feeling particularly bold – then you’d hunt. First, for your immediate manager. If they were in a meeting, out of the office, or simply lost in the depths of their own tasks, you waited. Days, sometimes. Once you got their signature, it was off to the next person, maybe the department head, then finance, and if it was a big purchase, perhaps even someone higher up. Each step meant more waiting, more chasing, more forms getting lost under piles of other papers. You’d call it in a "purchase requisition," but really, it was just a wish list sent on a slow, often frustrating journey, hoping it wouldn’t get stuck in limbo forever. The sheer lack of visibility was the worst part; you never knew where your request was, who had it, or when, if ever, it would finally get the nod.

Then, something shifted. We brought in an Enterprise Resource Planning (ERP) system. For many of us, it was a big, intimidating piece of software that promised to tie everything together. And one of the first things it tackled, one of the most immediate and tangible improvements, was how we handled those purchase requisitions and, crucially, their approvals. It wasn’t just a digital version of the old paper forms; it was a complete rethinking of the process, turning that chaotic jungle into a clear, well-lit path.

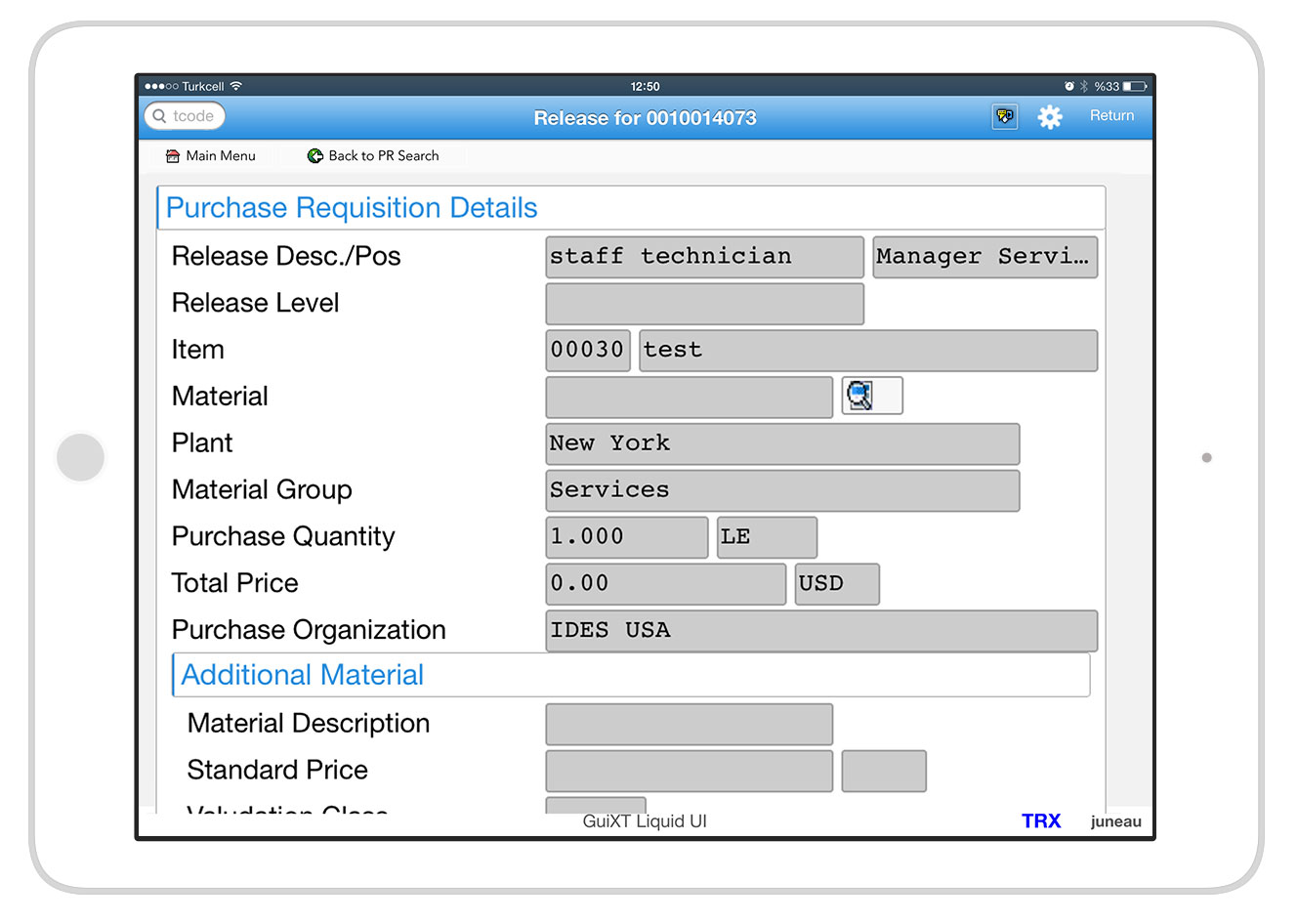

So, what exactly is a purchase requisition in the world of an ERP, and why does its approval matter so much? Imagine you’re at work, and you realize your team needs something. Maybe it’s a new set of ergonomic chairs because everyone’s complaining about back pain, or perhaps a specialized tool that will speed up a critical project. Instead of grabbing a piece of paper, you log into the ERP system. There, you find a section specifically for creating a "purchase requisition." Think of it as your formal way of saying, "Hey company, I need this thing, and here’s why." You type in the details: what you need, how many, an estimated cost, why you need it, and maybe even suggest a supplier if you have one in mind. You attach any relevant documents, like a quote or a project brief. It’s all there, neat and tidy, in a digital form.

Now, why does this digital wish list need an "approval"? This is where the magic, or rather, the responsible spending, happens. Companies, big or small, have budgets. They can’t just let everyone buy whatever they want, whenever they want, without any checks. That would be financial mayhem. Approval is the gatekeeper, making sure that what you’re asking for is actually needed, falls within budget, and aligns with the company’s rules and spending policies. It’s about accountability and making sure every dollar spent is a dollar spent wisely. Without a proper approval process, you’d have departments unknowingly duplicating purchases, spending too much, or even buying things that aren’t compliant with company standards or regulations. It’s the mechanism that keeps the financial gears turning smoothly, preventing unnecessary expenditures and ensuring that procurement is strategic, not just reactive.

Let me walk you through the journey of a purchase requisition in an ERP system, from its birth to its final blessing. It’s a structured dance, but one that moves with surprising speed once you get the hang of it.

First, the creation. As I mentioned, you, the user, log in and fill out the digital form. The ERP makes this easy. It often has drop-down menus for item categories, pre-filled fields for common information, and even budget codes you can select. This reduces errors and ensures all necessary information is captured from the start. No more deciphering shaky handwriting or missing crucial details. Once you’ve filled everything in, you hit "submit." This isn’t just sending an email; it’s formally entering your request into the system.

Next, the automated routing. This is where the ERP truly shines compared to the old paper method. The system doesn’t just send your request to one person; it knows exactly who needs to approve it, and in what order. How? Because it has predefined "approval workflows" built into it. These workflows are like digital maps. For example, if your request is for less than $500, it might just go to your direct manager. If it’s between $500 and $5,000, it might go to your manager and then the department head. For anything over $5,000, it might add a stop at the finance department, and maybe even a senior executive. These rules can be based on the amount, the type of item, the department making the request, or even the project it’s tied to. The system automatically sends a notification – usually an email or an in-system alert – to the first person in the approval chain, letting them know they have a pending request.

Then comes the review and decision. The approver logs into the ERP. They see your request, along with all the details you provided. They can review the item, the cost, the justification, and check if it aligns with their budget. They can also see the entire history of the request, if anyone else has already reviewed or commented on it. Based on their assessment, they have a few options:

- Approve: They click a button, and the request moves to the next person in the chain, or if they’re the last approver, it’s marked as "approved."

- Reject: If they don’t think it’s necessary, is out of budget, or for any other valid reason, they can reject it. Crucially, they usually have to provide a reason, which is communicated back to you. No more guessing why your request got shot down.

- Request More Information: Sometimes, an approver might need more details before making a decision. They can send it back to you with a query, and the process pauses until you provide the clarification.

This back-and-forth, if needed, happens all within the system, keeping a clear record of every communication. Once all the necessary approvals are gathered, the purchase requisition achieves its "approved" status. What happens then? The ERP can automatically trigger the next step, which is often the creation of a "purchase order" (PO) to send to the supplier, or it might notify the procurement team to take over and find the best vendor. The key is that the system ensures that no purchase order goes out without the proper internal approvals first.

The contrast between the old paper system and the ERP approach is stark. I remember spending hours physically tracking down signatures, forms getting lost between desks, and the sheer frustration of not knowing if my urgent request for a new piece of software was stuck on someone’s desk or simply forgotten. The delays were maddening. A simple purchase could take a week or more, holding up projects and causing unnecessary stress. With the ERP, those problems largely vanished. I could log in at any time, see the exact status of my request, who had it, and how long it had been with them. If it sat too long, the system could even send automated reminders. It brought a sense of calm and control to a process that used to be a source of constant low-level anxiety.

The benefits of moving to an ERP for purchase requisition approval go far beyond just making life easier for individual employees. They touch every part of the business:

First, and perhaps most importantly, there’s better budget control. Before ERPs, it was hard to get a real-time picture of spending. Managers might approve things without truly knowing their remaining budget, leading to nasty surprises at the end of the month. With an ERP, budgets can be integrated directly into the approval workflow. The system can flag a request if it pushes a department over budget, or even prevent it from moving forward until a budget override is approved. This means money is managed proactively, not just reconciled after it’s already spent. It helps prevent accidental overspending and ensures that financial resources are allocated thoughtfully.

Then there’s the significant boost in speed and efficiency. Imagine the time saved by not printing, carrying, and filing paper forms. Approvers can review requests from anywhere, on their computer or even a mobile device, as long as they have internet access. This dramatically cuts down approval times, meaning that necessary items are purchased and available much faster. Faster purchasing means projects move quicker, employees have the tools they need sooner, and the business operates more smoothly overall.

Transparency and visibility are also huge wins. As I mentioned, being able to see the status of any request at any time removes so much guesswork and frustration. This transparency isn’t just for the person making the request; managers can see all pending requests from their team, finance can track all approvals across the company, and procurement has a clear pipeline of what needs to be bought. This shared understanding reduces internal queries and allows everyone to plan better.

From a compliance standpoint, ERP purchase requisition approval is a lifesaver. It creates a complete, undeniable audit trail. Every step of the process – who requested what, when, who approved it, when they approved it, any comments, any rejections – is recorded and timestamped within the system. This is invaluable for internal audits, external compliance checks, and even in cases of dispute. It provides a clear record that demonstrates adherence to company policies and regulatory requirements. No more lost signatures or disputed verbal approvals; everything is documented digitally.

The system also helps in reducing errors. When you’re manually filling out forms and transcribing information, mistakes are bound to happen. Wrong item codes, incorrect quantities, miswritten vendor names. An ERP, with its standardized forms, drop-down selections, and often integration with supplier catalogs, minimizes these human errors. It ensures data consistency, which is vital for accurate financial reporting and efficient purchasing.

Finally, it allows for more strategic procurement. When the procurement team isn’t bogged down chasing signatures or fixing errors on paper forms, they can focus on higher-value activities. They can spend more time negotiating better deals with suppliers, identifying cost-saving opportunities, managing vendor relationships, and ensuring the company gets the best value for its money. The approval process, by ensuring planned and budgeted purchases, gives them the predictability they need to be more strategic. It empowers employees by giving them a clear, predictable way to initiate purchases, knowing their requests will be handled fairly and efficiently.

Of course, implementing and running an ERP approval system isn’t without its challenges. The initial setup can be quite complex. Defining all those approval workflows, figuring out who needs to approve what for every conceivable scenario, and setting up budget rules requires careful planning and collaboration across departments. It’s not a "set it and forget it" kind of deal. Getting everyone on board, from the newest employee to the most senior executive, requires good user adoption strategies and thorough training. People are used to their old ways, even if those ways were inefficient. Change can be uncomfortable, so clear communication about why the change is happening and how it benefits them is essential. Also, the ERP needs to integrate well with other systems, like our inventory management or accounting software, to truly get the most out of it. And finally, the approval matrices aren’t static; they need to be maintained and updated as the company grows, departments change, or new policies are introduced. It’s an ongoing effort.

My advice for anyone embarking on this journey is to start simple. Don’t try to build the most complex approval workflow on day one. Get the basics right, then gradually add more layers of sophistication. Communicate clearly with everyone involved about the new process and its benefits. Train, train, train – provide hands-on sessions, clear guides, and ongoing support. And most importantly, listen to user feedback. The people on the ground using the system every day will tell you what works and what doesn’t. Be prepared to review and refine your workflows as you go. It’s an iterative process, not a one-time project.

Looking ahead, I can see these ERP approval systems becoming even smarter. We’re already seeing more sophisticated analytics that can flag unusual spending patterns or potential risks, even before an approver sees the request. The rise of mobile approvals makes the process even more convenient, allowing managers to approve things on the go. And with the growing use of advanced technologies, I can imagine systems that might suggest the best vendor based on past purchases, current prices, and delivery times, or even use some clever algorithms to predict budget overruns before they happen. The goal is always to make the process even smoother, more intelligent, and less prone to human error, while maintaining that essential layer of oversight.

In the end, embracing ERP for purchase requisition approval was one of those transformations that, while initially daunting, brought immense relief and structure to our daily operations. It turned a cumbersome, error-prone, and often frustrating process into something efficient, transparent, and accountable. It moved us from a world of chasing signatures and lost papers to a world where a click of a button sets off a precise, digital chain reaction, ensuring that the company’s resources are spent wisely and purposefully. It truly changed how we bought things, not just making it easier, but making it smarter, and that’s a story worth telling.