I remember a time, not so long ago, when running our retail business felt a lot like navigating a dense fog. We were selling products, sure, and the cash register was ringing, which was always a good sign. But beyond that immediate sound, what did we really know? We knew what sold out quickly, because customers would complain when it wasn’t there. We knew what sat on shelves forever, because we’d trip over the boxes in the backroom. But understanding why things were happening, or how to make them better, felt like guessing games played in the dark.

Our inventory counts were often off, leading to embarrassing moments when we promised a customer something that simply wasn’t there, or worse, finding a forgotten pallet of seasonal goods months after the season had passed. Our sales figures, while tallied at the end of the day, rarely told us the full story. Were we truly profitable on every item? Which promotions actually worked, and which just ate into our margins? We were good at selling, but we weren’t smart about how we sold, or what we needed to sell next.

Then came the day we decided to bring in an Enterprise Resource Planning, or ERP, system. The name itself sounded intimidating, full of corporate jargon and complex technology. I pictured endless spreadsheets and consultants speaking in riddles. But our team, driven by a growing frustration with our own operational blind spots, knew we needed a change. We needed to lift the fog. What we discovered was not just a piece of software, but a fundamental shift in how we understood and managed our retail world. It was the beginning of our journey into ERP Retail Performance Monitoring, and it changed everything.

At its core, what this system promised was simple: a single, unified place for all our business information. Imagine every piece of data – from a single sale at the register to a large order from a supplier, from an employee’s work schedule to a customer’s loyalty points – all speaking to each other, all connected. This wasn’t just about collecting data; it was about making that data work for us, giving us a clear view of our performance, day in and day out.

The first area where the ERP truly shone for us was in understanding our sales. Before, our sales reports were basic totals. Now, we could drill down. We could see not just how much we sold, but what sold, when it sold, where it sold (if we had multiple locations), and who sold it. We could track sales by product category, by specific item, by brand, even by color or size. This granular detail was eye-opening. We quickly identified our true bestsellers, not just the items that felt popular. We saw patterns: certain products flew off the shelves on weekends, others were consistent performers throughout the week. We could spot trends appearing, giving us a crucial head start on ordering more of what customers wanted before we ran out.

For example, we noticed a particular brand of artisanal coffee mugs suddenly showing a consistent upward trend in sales across all our stores, especially on Tuesday mornings. This wasn’t just a fluke; it was a sustained pattern. Armed with this knowledge, we could adjust our orders, ensure those mugs were always in stock, and even place them in more prominent display areas, capitalizing on this newfound demand. Without the ERP, that trend would have been a vague feeling, if noticed at all.

Then came inventory management, which, for me, was a revelation. The old way involved manual counts, guesswork, and a lot of frantic phone calls to suppliers. With the ERP, every single item that entered our backroom was scanned and logged. Every item sold at the register was automatically deducted from our digital inventory. This meant our stock levels were updated in real-time. We knew precisely how many of those popular coffee mugs we had at any given moment, in each store, and in our warehouse.

This real-time visibility allowed us to do things we never dreamed of. We could set up automated reorder points: when the number of a specific item dropped below a certain threshold, the system would flag it, or even automatically generate a purchase order for our supplier. This dramatically reduced stockouts – those frustrating moments when a customer wants something, and you simply don’t have it. It also helped us avoid overstocking, preventing capital from being tied up in slow-moving inventory taking up valuable space. We could analyze inventory turnover rates, seeing how quickly different items moved, helping us make smarter purchasing decisions and even negotiate better terms with suppliers based on our consistent demand. The days of tripping over forgotten pallets were, thankfully, behind us.

Beyond just products, the ERP helped us understand our customers better. When integrated with our point-of-sale system, it allowed us to capture more than just a transaction. If customers signed up for our loyalty program, we could link their purchases to their profiles. This meant we could see their buying history, their preferred categories, and how often they shopped with us. This wasn’t about being intrusive; it was about serving them better.

We could identify our most loyal customers and offer them exclusive previews or personalized discounts. We could spot customers who hadn’t shopped with us in a while and send them a gentle reminder or a special offer to entice them back. We could even analyze purchase patterns to suggest complementary products – someone buying a specific type of coffee might also be interested in a new coffee maker or a particular brand of biscotti. This level of personalized engagement transformed our customer relationships from transactional to truly relational, fostering loyalty and repeat business.

The ERP’s reach extended further, giving us unprecedented insight into our supply chain. From the moment an order was placed with a vendor to the moment it arrived at our warehouse and then moved to our store shelves, we had visibility. We could track shipments, monitor vendor performance, and identify any bottlenecks. If a supplier consistently delivered late, the data would clearly show it, prompting us to either discuss improvements with them or explore alternative vendors. This visibility made our entire supply chain more efficient, reducing delays and ensuring our shelves were always stocked with the right products at the right time. We could even monitor the costs associated with different suppliers, ensuring we were getting the best value.

And, of course, there was the critical aspect of financial performance. Before the ERP, getting a clear picture of our profitability involved a lot of manual data compilation and often felt like looking at a rearview mirror. With the ERP, all our sales data, inventory costs, operational expenses, and even employee wages were consolidated. We could generate profit and loss statements, balance sheets, and cash flow reports with a few clicks. We could see which product lines were truly profitable after accounting for all associated costs. We could track our expenses in detail, identifying areas where we could cut back or invest more wisely. Budgeting became a much more informed process, moving from educated guesses to data-backed forecasts. We could understand our margins on different products, allowing us to make strategic decisions about pricing and promotions that truly boosted our bottom line, rather than just moving merchandise.

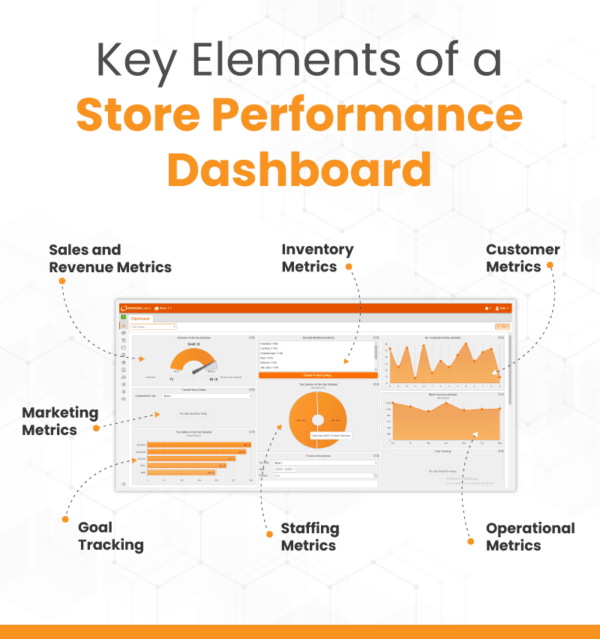

The real magic, though, wasn’t just in collecting all this data; it was in how the ERP allowed us to monitor it and turn it into actionable insights. The system provided us with dashboards – customizable screens that displayed key performance indicators (KPIs) at a glance. Imagine seeing your daily sales figures, current inventory levels for your top 10 products, customer acquisition rates, and even your profit margin percentage, all on one screen, updated in real-time. This eliminated the need to comb through countless reports. It gave us a pulse on our business every single moment of every day.

We used these dashboards to hold daily huddles. Instead of discussing vague feelings about how sales were going, we could look at the actual numbers. "Why did coffee mug sales dip yesterday?" we might ask. The data would then allow us to investigate: Was there a stockout? Was a competitor running a promotion? Was there a problem with the display? This proactive approach meant we could address issues immediately, often before they became major problems.

We also set up custom reports. For instance, we created a report that showed us the sales performance of each employee, allowing us to identify our top performers and offer targeted training to those who needed a little extra support. We developed reports that analyzed the effectiveness of our marketing campaigns, showing us which channels brought in the most profitable customers. This allowed us to allocate our marketing budget more effectively, investing in what worked and adjusting what didn’t.

Our journey wasn’t without its challenges. Implementing an ERP system is a significant undertaking. There was a learning curve for everyone, from the front-line sales associates to the management team. Data migration – moving all our existing information into the new system – was a painstaking process. There were moments of frustration when reports didn’t look quite right or when someone struggled with a new workflow. But through consistent training, clear communication, and a shared understanding of the long-term benefits, we pushed through.

What we gained was immense. Our decision-making became sharper, faster, and far more accurate. We moved from reactive problem-solving to proactive strategic planning. Our team felt more empowered because they had access to the information they needed to do their jobs better. They could check stock levels instantly for a customer, provide accurate pricing, and understand how their efforts contributed to the overall success of the business.

The financial return on our investment in the ERP was clear. Reduced stockouts meant fewer lost sales. Optimized inventory meant less capital tied up and lower storage costs. Targeted promotions meant higher conversion rates and better margins. Improved supply chain efficiency meant lower operational costs. And happier, more loyal customers meant consistent, growing revenue. Our business became more agile, more responsive to market changes, and ultimately, more profitable.

Today, the fog has lifted. Our retail business operates with a clarity and precision that was unimaginable just a few years ago. ERP Retail Performance Monitoring isn’t just a technical capability for us; it’s the heartbeat of our operation. It’s the constant, reliable stream of information that empowers every decision we make, from the smallest pricing adjustment to the largest strategic expansion. It’s the assurance that we’re not just selling products, but building a sustainable, successful retail future, guided by the undeniable truth of our data. And for any retail business still navigating that fog, I can only say this: the path to clarity begins with understanding your numbers, and an ERP system is your most powerful guide.