I remember those days vividly, a knot of anxiety permanently residing in my stomach. Our small manufacturing business, a passion project that had grown into something substantial, was teetering on the edge of chaos, and the main culprit? Our suppliers. Not that they were bad people, mind you, but the process, or lack thereof, was simply unmanageable. We’d place orders, often large ones, for raw materials, components, or even packaging, and then… we’d wait. And worry.

The phone calls were endless. “Is the steel shipment coming today?” “Did the circuit boards leave their factory?” “Where are those special screws we need for the next batch?” Most of the time, the answers were vague, or worse, completely wrong. We’d be told a delivery was imminent, only for nothing to arrive. Production lines would grind to a halt. Our skilled workers would stand idle, costing us money by the minute. Our customers, who relied on us for timely products, would grow impatient. I felt like a juggler, constantly dropping balls, trying to keep too many plates spinning with my eyes closed.

Our inventory was a mess too. Because we couldn’t trust delivery dates, we’d often over-order, just in case. Our warehouse was overflowing with materials we didn’t need immediately, tying up capital. Other times, we’d run completely out of a critical item, leading to desperate, expensive rush orders. It was a vicious cycle of feast or famine, all stemming from a fundamental lack of visibility into what our suppliers were doing, and when they were actually going to deliver. We had spreadsheets, sure, but they were outdated the moment someone saved them. Email chains were long and confusing. And don’t even get me started on the phone calls, each one a fresh attempt to piece together a fragmented puzzle.

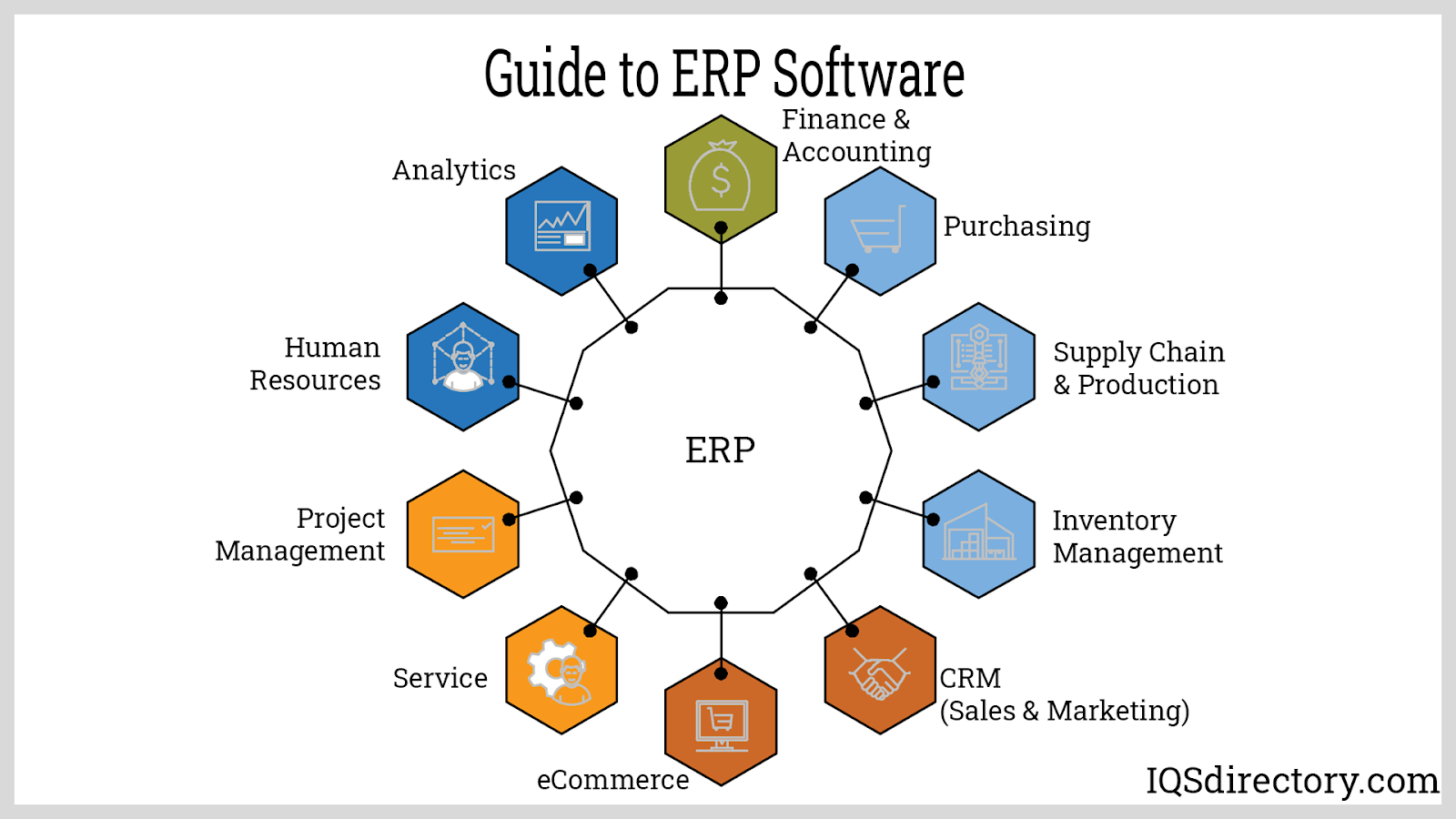

I knew we couldn’t go on like this. The stress was immense, and our growth was being stifled. We were losing money, frustrating our team, and risking our reputation. It was clear we needed a better way, a system that could bring order to the chaos. That’s when I started hearing whispers about something called ERP, or Enterprise Resource Planning. Honestly, the name sounded a bit intimidating at first, like something only huge corporations used. But as I dug deeper, I realized it was exactly what we needed, especially for getting a handle on our supplier deliveries.

The idea was simple enough: an ERP system is like a central nervous system for your entire business. It connects all the different parts – sales, production, inventory, finance, and crucially, procurement and supplier management – so they can talk to each other and share information in real-time. For me, the magic word was "real-time." Imagine knowing exactly where every single order from every single supplier was, at any given moment. That sounded like a dream.

The journey to implementing an ERP system wasn’t without its bumps, I won’t lie. It felt like learning a new language for the whole company. There was training, data migration (which felt like moving mountains of old paper records into a digital world), and a fair bit of initial grumbling from some team members who preferred the "old ways." But we pushed through, because the vision of a calmer, more efficient future was too compelling to ignore.

Once we got it up and running, the change for our supplier delivery monitoring was almost immediate and utterly profound. It was like someone finally turned on the lights in a dark room.

Here’s how it changed things, piece by piece, for our supplier deliveries:

1. A Single Source of Truth for Purchase Orders:

Before ERP, a purchase order (PO) was just a document we sent. After that, it disappeared into a black hole until something showed up, or didn’t. With the ERP system, every single PO we issued was immediately recorded and tracked within the system. It had a unique ID, a clear list of items, quantities, agreed prices, and most importantly, an expected delivery date. This wasn’t just a static record; it was a living entry that everyone in the company could see. Our procurement team, our production managers, our warehouse staff, even our sales team – everyone knew what was ordered and when it was expected. No more conflicting information or frantic searches through email archives.

2. Real-time Status Updates, Not Just Guesses:

This was the game-changer. Our ERP system allowed us to integrate with our suppliers, in various ways. For some, it was a direct connection, where they could update the status of our orders directly in our system. For others, it meant our procurement team could easily log in and update the status based on confirmation emails or tracking numbers. We could see when an order was "confirmed," "in production," "shipped," and eventually, "delivered." We could input tracking numbers directly, letting us follow a package’s journey from their factory to our loading dock. The days of simply waiting and wondering were over. If a truck was delayed, we knew about it, often before the truck driver did!

3. Automated Alerts and Notifications:

Remember those frantic phone calls I mentioned? They became a thing of the past. Our ERP system was set up to send automated alerts. If a delivery was marked as "shipped" but hadn’t arrived by its expected date, the system would flag it. Our procurement manager would get an email, and a notification would pop up on their dashboard. This meant we could proactively reach out to the supplier before it became a crisis, rather than reacting only after production was stalled. We could see potential delays coming down the pipeline, giving us precious time to adjust our production schedule, or find an alternative solution if necessary. It turned us from reactive fire-fighters into proactive planners.

4. Supplier Performance Scorecards:

This was a feature I never knew we needed so badly. The ERP system collected data on every delivery from every supplier. It tracked things like on-time delivery rates, how often orders were complete and accurate, and even the quality of the items received (when integrated with our quality control modules). This data was then compiled into easy-to-read "scorecards" for each supplier. Suddenly, we weren’t just guessing who our reliable suppliers were; we knew. We could see who consistently delivered on time and who often fell short. This was invaluable for making informed decisions: rewarding our best suppliers with more business, or working closely with underperforming ones to help them improve, or even finding new partners if improvement wasn’t possible. It transformed our relationships with suppliers from transactional to strategic.

5. Better Communication, Less Hassle:

Many ERP systems have built-in communication tools. We could add notes to specific purchase orders, share documents, or even send messages to suppliers directly through the system. This centralized all communication related to an order, so everyone involved knew exactly what was said and by whom. No more digging through individual inboxes or trying to remember who talked to whom. Everything was right there, attached to the relevant order.

6. Inventory Optimization and Production Planning:

With reliable delivery information, our inventory management became much smarter. We could reduce our safety stock levels because we trusted the delivery schedules. This freed up valuable capital and warehouse space. Our production planning also improved dramatically. We could schedule production runs with much greater confidence, knowing that the required materials would actually arrive when needed. This meant smoother operations, less downtime, and ultimately, higher output with fewer headaches.

7. Financial Clarity and Accuracy:

The ERP system also connected supplier deliveries to our finance department. When materials arrived, the system could automatically match the delivery receipt to the original purchase order and then to the supplier’s invoice. This eliminated discrepancies, sped up invoice processing, and ensured we only paid for what we actually received and ordered. It brought a level of financial control and accuracy that was previously unimaginable.

The impact on our business was nothing short of transformative. The stress began to lift. My team felt more confident and empowered. Our production lines hummed with efficiency. Our customers noticed the difference too – fewer delays, more consistent product availability, and a general sense of reliability from our company. We were no longer just making products; we were building trust, both with our suppliers and our customers.

I remember one particular instance. A critical component from an overseas supplier was showing a two-day delay in the ERP system. In the past, this would have been a frantic scramble, potentially shutting down our assembly line. But because we saw the alert early, our production manager was able to quickly adjust the schedule, shifting a different product line forward for those two days. When the delayed components finally arrived, our team seamlessly transitioned back to the original plan, without a single moment of idle time. That kind of agility, that kind of calm in the face of a potential disruption, was something we could only dream of before.

For anyone out there still struggling with unreliable supplier deliveries, still juggling those metaphorical balls in the dark, my advice is this: don’t be afraid of technology. An ERP system might seem like a big step, and it is. But the rewards, particularly in how it helps you monitor and manage your supplier deliveries, are immeasurable. It’s not just about installing software; it’s about investing in peace of mind, operational efficiency, and the future growth of your business.

We learned that choosing the right ERP system, one that fits your company’s specific needs and size, is crucial. We focused on getting our team on board from the start, explaining the ‘why’ behind the change. We also realized that data accuracy is king – the system is only as good as the information you feed it. And finally, it’s a journey of continuous improvement. We’re always finding new ways to use our ERP to refine our processes, strengthen our supplier relationships, and ensure our supply chain remains robust and reliable.

Looking back, that constant knot of anxiety in my stomach is gone. Replaced by a quiet confidence. The chaos has been replaced by clarity. ERP supplier delivery monitoring wasn’t just a technical upgrade for us; it was a fundamental shift in how we operated, allowing us to build a more resilient, responsive, and ultimately, more successful business. It’s a story of how a seemingly complex piece of software became the simplest solution to one of our biggest problems, turning uncertainty into a predictable flow, and turning worries into opportunities.