From Chaos to Clarity: My Story of Mastering ERP Supplier Invoice Processing

Remember those days? The ones where our accounts payable department looked less like an office and more like a paper-strewn battlefield? Boxes of invoices, stacks on every desk, sticky notes plastered everywhere, and the constant hum of the scanner battling with the frantic ringing of the phone. Suppliers calling, "Where’s my payment?" Internal teams asking, "Did we pay for X yet?" It was a special kind of daily chaos.

My name’s Sarah, and I used to be right there in the thick of it. My job involved making sure our suppliers got paid accurately and on time. Sounds simple, right? It was anything but. Every single invoice that came in – whether by mail, email, or fax – was a potential landmine. And let me tell you, processing supplier invoices was the biggest, most time-consuming, and error-prone part of my day.

The Nightmare Before ERP: A Labyrinth of Paper and Problems

Let me paint you a picture of what our supplier invoice processing looked like before we embraced an Enterprise Resource Planning (ERP) system:

- The Arrival: Invoices would arrive in a myriad of ways. Some snail mail, some emailed as PDFs, some even faxed. Each had to be physically handled, opened, sorted.

- Manual Data Entry: The Human Error Hotspot: Once received, someone – usually me or a colleague – had to manually input every single detail into our accounting system. Vendor name, invoice number, date, line items, quantities, prices, tax codes. One tiny typo, one slipped finger, and we had a problem. And trust me, these typos happened. Often.

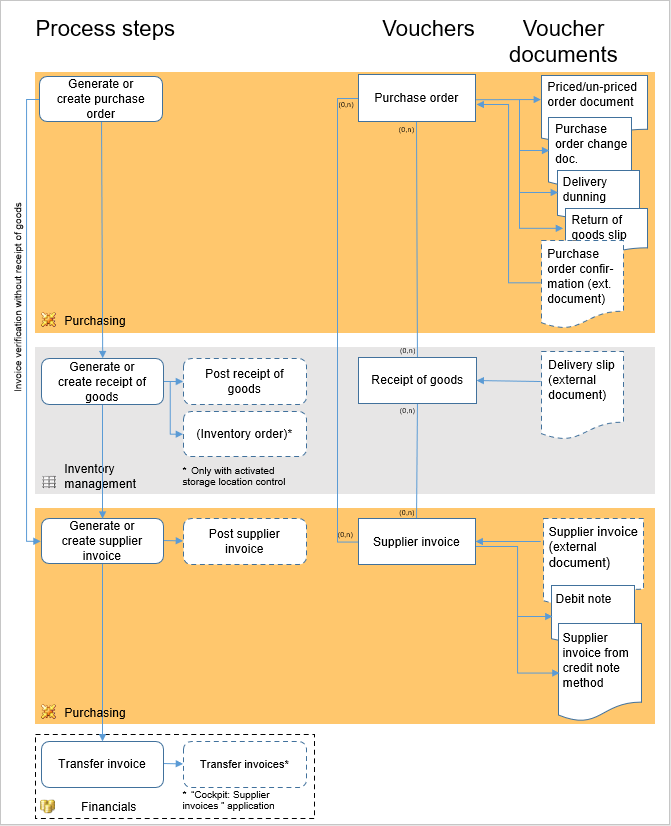

- The Matching Game (or Guessing Game): Then came the detective work. We had to match the invoice to the original Purchase Order (PO) and the Goods Receipt Note (GRN) – the document confirming we actually received what we ordered. This often meant digging through filing cabinets or endless email chains. If anything didn’t match, it was a chase. A phone call to purchasing, an email to the warehouse, a frantic search for the right paperwork.

- The Approval Gauntlet: Once matched (or mostly matched), the invoice needed approval. Depending on the amount or department, it might need one, two, or even three signatures. This meant physically walking invoices around the office, leaving them on desks, hoping someone would see it, sign it, and pass it on. Ever had an invoice get "lost" under a pile of papers on someone’s desk for a week? Yeah, me too.

- Payment and Filing: Finally, after all that, the payment would be scheduled. Then, the physical invoice, PO, and GRN were stapled together and filed away. In a physical cabinet. Which meant if we ever needed to find it again for an audit or query, it was another treasure hunt.

The consequences? Late payments, strained supplier relationships, duplicate payments, missed early payment discounts, and a whole lot of stress. Our team was constantly reactive, putting out fires instead of focusing on strategic financial management. We knew there had to be a better way.

The Dawn of a New Era: Enter ERP Supplier Invoice Processing

One day, our management team decided enough was enough. We were growing, and our manual processes simply couldn’t scale. That’s when we started talking about an ERP system. At first, it sounded like this huge, complex beast of software. But as we delved deeper, we realized its potential, especially for our beleaguered accounts payable department.

An ERP system is essentially a centralized software platform that integrates all of a company’s core business processes – from finance and HR to manufacturing and supply chain. For us, the biggest game-changer was how it handled supplier invoices. It promised to take us from that paper-strewn battlefield to a streamlined, digital highway. And it delivered.

How ERP Magically Transforms Invoice Processing: A Beginner’s Guide

Let me walk you through how our supplier invoice processing looks now, thanks to our ERP. It’s not magic, but it certainly feels like it sometimes!

Step 1: Automated Invoice Capture – No More Stacks!

This is where the transformation truly begins. Instead of invoices arriving in a messy pile, they now enter our system digitally:

- Email Integration: Suppliers email invoices directly to a dedicated email address. Our ERP system monitors this inbox, automatically pulling in the attached PDF invoices.

- Optical Character Recognition (OCR): This is the clever bit! The ERP uses OCR technology, often powered by Artificial Intelligence (AI), to "read" the invoice. Think of it like a super-smart assistant that scans the document and extracts all the critical information: vendor name, invoice number, date, total amount, line items, quantities, unit prices, and tax details. It automatically populates these fields in the system, eliminating manual data entry.

- Supplier Portals: Some of our larger suppliers can even upload their invoices directly into our ERP via a secure online portal. This bypasses email entirely and ensures data is structured from the source.

My take: This alone saved us countless hours. No more opening envelopes, no more frantic typing. The data is in the system almost instantly and with far greater accuracy.

Step 2: Intelligent Data Validation & Matching – The Digital Detective

Once the data is captured, the ERP doesn’t just blindly accept it. This is where the real intelligence comes in for supplier invoice processing: