I remember standing on the factory floor for the first time, a whirlwind of sights and sounds. The rhythmic clang of metal, the hiss of pneumatic presses, the steady hum of conveyors carrying half-finished products down their lines. It was a symphony of organized chaos, or so it seemed to my fresh eyes. I was new to the world of manufacturing, tasked with understanding how we actually made things, and honestly, I felt like a tiny boat lost in a vast ocean. Orders were coming in, raw materials were arriving, machines were running, and somehow, finished goods were supposed to magically appear on time, every time. The sheer complexity of coordinating it all felt overwhelming.

My initial days were spent chasing information. Where was that critical component we needed for Order #1234? Was Machine A going to be free by Tuesday, or was it tied up with the big export batch? Did we have enough skilled hands for the second shift, or would we fall behind? Everyone had a piece of the puzzle – the sales team knew what customers wanted, purchasing knew what we ordered, the shop floor supervisors knew what was happening right now, and the warehouse knew what we had in stock. But stitching all those pieces together into a coherent, real-time picture? It felt like trying to assemble a jigsaw puzzle in the dark, with pieces constantly changing shape. We relied on whiteboards, spreadsheets, frantic phone calls, and often, the gut feeling of experienced foremen. It was reactive, stressful, and prone to costly mistakes.

Then, someone introduced me to the concept of an Enterprise Resource Planning (ERP) system. At first, it sounded like another layer of jargon, another intimidating piece of software. But as I dug deeper, I realized it was designed to be the central nervous system of a business. And within that system, there was a particular tool that truly caught my attention, a game-changer for someone like me trying to make sense of the factory floor: the ERP Production Planning Dashboard.

Imagine, if you will, stepping into the cockpit of a sophisticated aircraft. You’re surrounded by screens, dials, and indicators, each displaying vital information about the plane’s status, its journey, and its environment. That’s what the Production Planning Dashboard felt like to me. It wasn’t just a collection of numbers; it was a visual representation of our entire manufacturing operation, laid out in an easy-to-digest format. It promised to take all those disparate pieces of information – sales orders, inventory levels, machine availability, workforce schedules, material deliveries – and present them together, in one place, updated constantly. This wasn’t just data; it was actionable insight, the kind that could transform our reactive chaos into proactive control.

My journey with the dashboard began with understanding its core purpose. At its heart, a Production Planning Dashboard is about visibility and control. It’s designed to answer critical questions instantly: What are we supposed to be making? What are we making right now? What resources do we have? What resources do we need? And are we on track to meet our commitments?

One of the first things I learned to appreciate was the dashboard’s ability to show real-time operational status. Before, if I wanted to know the progress of a specific order, I’d have to walk the floor, ask supervisors, maybe even check a physical job card. Now, I could see it on a screen. A quick glance would tell me which production lines were running, which machines were idle, and where bottlenecks might be forming. Colors often played a big role here: green for on schedule, yellow for potential delays, red for critical issues. It was like having X-ray vision into the factory. This immediate insight allowed us to catch problems much earlier than before. Instead of discovering a delay hours or even days after it started, the dashboard would flag it almost as it happened, giving us a fighting chance to intervene.

Then came the magic of Order Management. Our customers placed orders, and those orders needed to travel a specific path through our factory. The dashboard transformed this abstract journey into a tangible timeline. I could click on a customer order and see its status: raw materials ordered, materials received, production scheduled, currently in process at Station 3, quality control pending, ready for shipment. This level of transparency was revolutionary. Sales could give customers accurate updates without calling the factory floor, and we in production could prioritize based on delivery dates and customer importance. It made the entire process feel less like a guessing game and more like a carefully orchestrated sequence of events.

Inventory Management was another area where the dashboard shone brightly. Oh, the nightmares of inventory! Too much raw material tying up cash and warehouse space. Too little, and production grinds to a halt. Too many finished goods sitting unsold, or not enough to meet demand. The dashboard provided a constantly updated view of our inventory levels across the board. Raw materials, work-in-progress, finished goods – it was all there. More importantly, it linked inventory to our production schedule and sales forecasts. It could tell us, for example, "You have enough Widget A for the next two weeks’ production, but you’ll be short on Gizmo B by next Monday unless the new shipment arrives." This proactive alerting, often powered by Material Requirements Planning (MRP) modules within the ERP, allowed our purchasing team to place orders just-in-time, minimizing holding costs and preventing stockouts that could cripple production. I saw firsthand how this reduced wasted materials and improved our cash flow.

The heart of the factory’s rhythm is its Production Scheduling. This is where raw materials, machine capacity, and human effort converge to create products. Before the dashboard, scheduling felt like a dark art, practiced by a few seasoned veterans who held complex schedules in their heads or on sprawling, taped-together charts. The dashboard brought this into the light. It displayed our production calendar, showing what was planned for each machine, each line, each shift. It allowed us to drag and drop jobs, re-prioritize based on new urgent orders, and instantly see the ripple effect of those changes on other scheduled tasks. When a machine broke down, we could quickly reallocate jobs to available equipment, minimizing disruption. This dynamic scheduling capability meant we could adapt to unforeseen circumstances with agility, rather than being derailed by every small hiccup.

This led naturally to understanding Capacity Planning. It’s not just about what you need to make, but what you can make. The dashboard helped us visualize our machine capacity, our labor capacity, and even our tooling availability. It would highlight if we were over-scheduling a particular machine, indicating a potential bottleneck, or if we had idle capacity that could be utilized more effectively. This was crucial for preventing burnout among our team and avoiding costly overtime, while also ensuring we weren’t turning away profitable orders because we thought we were too busy. It helped us make informed decisions about investments in new machinery or hiring additional staff, based on real data, not just assumptions.

Monitoring the Shop Floor Control became much more straightforward. As jobs moved from one workstation to another, or as components were assembled, the dashboard would update their status. This wasn’t just about tracking; it was about performance. We could see how long a job was taking at each stage, compare it to our standard times, and identify areas where efficiency could be improved. Were certain operators consistently faster? Was a particular machine always running slower than expected? These insights were invaluable for continuous improvement initiatives and for training our workforce more effectively. It empowered our supervisors to move from constantly reacting to problems to actively optimizing their operations.

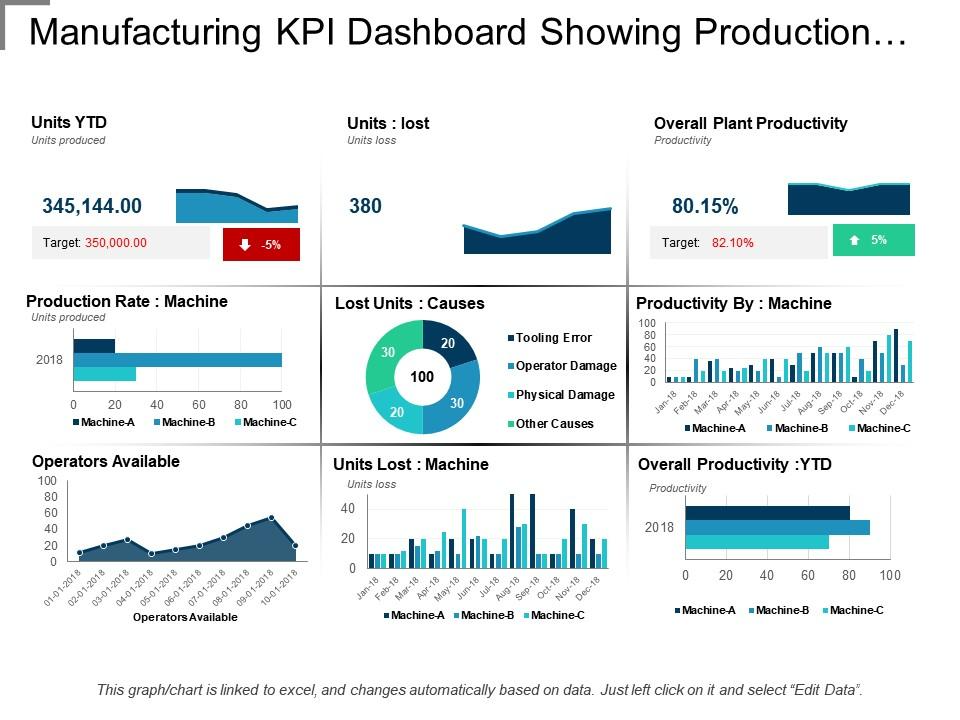

Perhaps one of the most compelling aspects for me was how the dashboard presented Key Performance Indicators (KPIs). These weren’t just abstract numbers; they were the heartbeat of our success. Things like "On-Time Delivery Rate," "Production Cycle Time," "Scrap Rate," "Machine Utilization," and "Labor Efficiency" were displayed prominently. Seeing these metrics visually, often with trend lines, helped us understand our performance at a glance. We could track progress towards our goals, celebrate successes, and most importantly, pinpoint areas that needed immediate attention. It shifted our focus from simply producing goods to producing goods efficiently and effectively. This data-driven approach replaced guesswork with hard facts, making our team meetings more productive and our improvement efforts more targeted.

The overall impact of the ERP Production Planning Dashboard on our manufacturing operations was profound. It fostered improved decision-making at every level. Managers could make strategic choices about resource allocation, production priorities, and customer commitments with confidence, backed by accurate, up-to-date information. It significantly reduced operational costs by minimizing waste, optimizing inventory, and improving labor efficiency. Our efficiency soared because we spent less time looking for information and more time acting on it.

Customer satisfaction also saw a remarkable improvement. With accurate information about production schedules and delivery dates, our sales team could set realistic expectations and communicate effectively. This transparency built trust and strengthened customer relationships, turning frantic calls about delayed orders into routine updates.

One of the biggest shifts I observed was in proactive problem-solving. Instead of being constantly blindsided by issues, the dashboard gave us the tools to anticipate potential problems. If a critical raw material shipment was delayed, the system would immediately highlight which production orders would be affected, allowing us to adjust schedules or explore alternative suppliers before it became a crisis. This foresight was invaluable.

It also helped break down information silos. The dashboard became a common reference point for everyone, from sales to purchasing to production to shipping. Everyone was looking at the same version of the truth, which fostered better communication and collaboration across departments. No more "my data says this, your data says that." It was a unified picture.

Of course, it wasn’t a magic bullet. Implementing and effectively using an ERP Production Planning Dashboard requires effort. Data accuracy is paramount; "garbage in, garbage out" applies here more than anywhere else. We had to invest in training our staff, ensuring everyone understood how to input data correctly and how to interpret the information presented on the dashboard. There was an initial learning curve, and some resistance to change, as people transitioned from familiar, if inefficient, methods to a new way of working. But the long-term benefits far outweighed these initial challenges.

Looking back, my journey from a confused novice on the factory floor to someone who could confidently navigate our production landscape was largely thanks to this tool. It transformed manufacturing from a bewildering maze into a clear, manageable process. The ERP Production Planning Dashboard isn’t just software; it’s an enabler, a strategic asset that empowers businesses to produce more efficiently, adapt more quickly, and serve their customers better. It’s a testament to how technology, when applied thoughtfully, can bring clarity, control, and calm to even the most complex environments. And for someone like me, who started with no clue, it was like being handed the keys to the kingdom, allowing me to finally understand the beautiful, intricate dance of making things. It wasn’t just about managing production; it was about mastering it.