I remember a time, not so long ago, when managing our company’s IT assets felt like trying to herd a thousand digital cats, each one with its own mischievous agenda. We had servers humming in the data center, laptops scattered across departments, monitors peering from every desk, and a dizzying array of software licenses that seemed to multiply overnight. Each piece of technology, big or small, had its own story, its own cost, and its own moment of either glory or spectacular failure. Keeping track of all of it, from the moment we first thought about needing it to the day it breathed its last digital breath, was a never-ending saga of spreadsheets, whispered rumors, and frantic searches. That’s where the IT asset lifecycle came in, and later, where Enterprise Resource Planning (ERP) truly changed everything for me and my team.

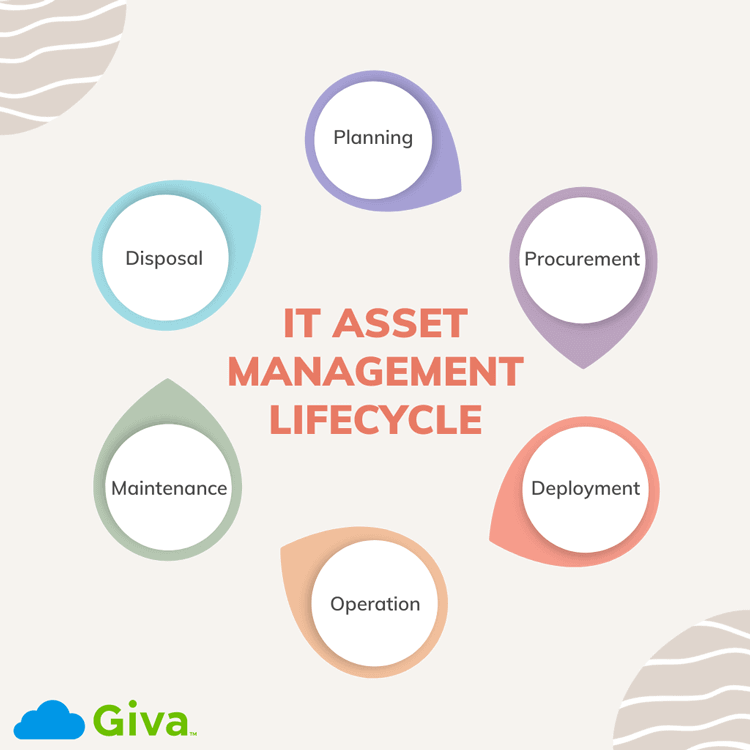

You see, every IT asset, whether it’s a mighty server or a humble mouse, goes through a predictable journey. We call it the IT Asset Lifecycle, and it’s essentially the roadmap of an asset’s entire existence within an organization. It starts with an idea, then procurement, moves through deployment, daily operation, monitoring, and finally, its eventual retirement. Before ERP, managing this journey was less like a roadmap and more like navigating a dense, uncharted jungle with a blindfold on. I’d seen firsthand the chaos: forgotten equipment, expired software licenses costing us a fortune, security vulnerabilities due to outdated systems, and the sheer frustration of trying to piece together an accurate inventory for an audit. It was a mess, and frankly, it was costing us a lot of money and a lot of sleep.

Then, we started looking into ERP systems. At first, it sounded like another layer of complexity, a big, scary piece of software. But as I dug deeper, I realized ERP wasn’t just about finance or HR; it had a powerful role to play in streamlining IT Asset Management (ITAM), especially when it came to tracking assets through their complete lifecycle. It promised to bring all those disparate pieces of information – purchasing data, maintenance records, user assignments, software installations – into one unified system. For someone who’d spent years chasing down asset tags and reconciling conflicting reports, the idea of a single source of truth was nothing short of revolutionary.

Let me walk you through how ERP transformed each stage of our IT asset lifecycle, from the very beginning to the very end.

The Spark of Need: Planning and Procurement

Before ERP, our planning and procurement process for IT assets often felt like a series of educated guesses, sometimes not so educated. A department would put in a request for 20 new laptops, another would ask for a specific software, and often, these requests wouldn’t be cross-referenced with what we already had, what was underutilized, or what was coming off lease. We’d over-order, under-order, or worse, buy something we already owned but couldn’t locate. Inventory management was a constant struggle, leading to excess stock gathering dust or sudden shortages that halted productivity. It was a budgetary nightmare, with unexpected costs popping up like digital whack-a-moles.

With ERP, this stage became a strategic exercise instead of a reactive scramble. The system integrated our demand forecasting with our current inventory and even our financial data. When a department needed new equipment, their request would go into the ERP system. The system could then instantly show us what we had in stock, what was available from previous projects, or what was due for an upgrade. It allowed us to analyze historical data on asset usage and failure rates, giving us a much clearer picture of future needs. Procurement suddenly became intelligent. We could track vendor contracts, compare prices, and automate purchase orders directly through the ERP. This meant better negotiation power, less redundant buying, and a significant reduction in our procurement costs. I remember the relief of finally having a clear, data-driven answer to "Do we really need this?" instead of just a shrug and a guess. It also made budget allocation much more precise, as we could see exactly where our money was going and how it aligned with our IT asset strategy.

Bringing Them Home: Deployment and Integration

Once we’d bought something, the next challenge was getting it into the hands of the right people, configured correctly, and properly recorded. In the old days, a new shipment of laptops meant a flurry of manual updates to a spreadsheet, sticking on handwritten asset tags, and hoping no one forgot a step. We’d often lose track of assets before they even reached their users. Software installations were a patchwork, and ensuring everyone had the correct licenses was a constant headache, especially during audits when we had to prove compliance.

ERP brought order to this chaos. When new IT assets arrived, they were immediately scanned into the system. Each asset received a unique identifier, and all relevant details – serial number, model, purchase date, warranty information – were automatically captured. This was linked directly to the purchase order we’d created earlier. Deployment became a standardized process. We could assign an asset to a specific user, department, or location within the ERP, and the system would track its journey. Software license management became integrated as well; we could allocate licenses, track installations, and ensure compliance without ever leaving the system. No more "lost" assets sitting in a storage closet, no more scrambling to find out who had what. It provided a real-time view of our IT landscape, making initial setup and subsequent reassignments much smoother. I personally felt a weight lift off my shoulders knowing that from the moment an asset entered our doors, its identity and location were accounted for.

The Daily Grind: Operation and Maintenance

This is where the rubber meets the road. IT assets are not static; they need care, updates, and occasional repairs. Before ERP, our maintenance was largely reactive. A user would report a problem, and we’d scramble to find the asset’s history, its warranty status, and who was responsible for fixing it. Preventative maintenance schedules were theoretical at best, often overlooked amidst daily fires. Software updates were manual and inconsistent, leading to security gaps. Managing warranties was a nightmare; we’d often miss deadlines or forget an asset was still under coverage, paying for repairs we didn’t need to.

With ERP, the operational phase transformed. The system became our central hub for all things maintenance. We could schedule preventative maintenance checks automatically, ensuring servers were updated, and laptops were serviced on time. When an issue arose, the help desk could pull up an asset’s complete history – who used it, when it was last serviced, its configuration – all from one screen. This drastically sped up troubleshooting and resolution times. Warranty information, captured during procurement, was readily available, preventing us from incurring unnecessary repair costs. The ERP also helped us track incidents, identify recurring issues with specific asset types, and even manage spare parts inventory. This proactive approach not only extended the life of our assets but also minimized downtime, which directly impacted productivity across the entire organization. I saw a significant drop in urgent support tickets because we were catching problems before they became emergencies.

Keeping an Eye Out: Monitoring and Tracking

Knowing where your assets are and what they’re doing at any given moment is critical, but it was incredibly difficult before ERP. Inventory audits were dreaded events, requiring days of manual counting and cross-referencing, often yielding inconsistent results. We constantly worried about regulatory compliance – proving we had the right software licenses, that our data was secure on retired devices, or that we met industry standards. Security was another big concern; how could we protect assets we couldn’t even accurately locate or identify?

ERP gave us unparalleled visibility. Through its integration with various IT systems, it provided real-time monitoring of our assets. We could track asset location, status (in use, in repair, in storage), and even usage patterns. This real-time data allowed us to optimize asset utilization, identify underused equipment that could be repurposed, and make informed decisions about future purchases. For compliance, the ERP system became invaluable. It could generate comprehensive reports on software licenses, demonstrating our adherence to agreements. It helped us track the chain of custody for sensitive equipment, crucial for security audits. The ability to see our entire IT landscape at a glance, through dashboards and customizable reports, was game-changing. It transformed inventory audits from agonizing scavenger hunts into straightforward data pulls. We could confidently tell auditors exactly what we had, where it was, and who was using it, which gave everyone a lot more peace of mind. This deep insight helped us tighten our security posture as well, by quickly identifying non-compliant or vulnerable assets.

Time to Say Goodbye: Retirement and Disposal

Eventually, all IT assets reach the end of their useful life. Whether it’s an old server, a broken laptop, or an outdated piece of software, its journey must conclude. Before ERP, this stage was often haphazard and risky. Old equipment would pile up in storage rooms, forgotten. Data security was a major concern; were we really wiping sensitive information properly before disposal? Environmental regulations were often an afterthought, and tracking the financial implications, like depreciation and remaining asset value, was a manual accounting headache.

ERP brought structure and security to the retirement phase. When an asset was deemed obsolete or no longer functional, its status was updated in the system. The ERP would then trigger a series of steps: secure data wiping procedures, ensuring no sensitive information left our premises, followed by tracking the asset for proper environmental disposal or recycling, adhering to all local and national regulations. The system also automatically handled the financial aspects, calculating depreciation, reporting on remaining asset value, and supporting decisions on whether to sell, scrap, or donate. We could also identify assets that, while no longer suitable for their original purpose, could be redeployed for less demanding tasks, extending their value. This comprehensive approach minimized risks – both financial and security-related – and ensured we were being responsible corporate citizens. I recall the relief of knowing that when an asset left our control, its journey was properly documented and its data securely handled.

Beyond the Stages: The Holistic ERP Advantage

Looking back, the transformation was profound. ERP wasn’t just a tool for individual stages; it created a connected ecosystem for our IT assets.

Cost Optimization: The ability to see the full cost of ownership for each asset, from procurement to disposal, allowed us to make smarter purchasing decisions and identify areas for savings. We could negotiate better deals with vendors, extend asset lifecycles through proactive maintenance, and avoid costly compliance penalties.

Enhanced Security: By having a complete, accurate, and real-time inventory of all IT assets, we could identify vulnerabilities faster, ensure all devices were patched and updated, and better control access to sensitive equipment. This significantly bolstered our overall security posture.

Simplified Compliance and Audits: What used to be a stressful, time-consuming ordeal became a much smoother process. With all asset data centralized and easily reportable, we could quickly demonstrate compliance with software licenses, regulatory requirements, and internal policies.

Strategic Decision Making: The rich data collected by the ERP system provided invaluable insights. We could analyze asset performance, predict failure rates, identify trends in asset utilization, and make data-driven decisions about future IT investments. It moved us from reactive firefighting to proactive, strategic planning.

Unified View: The true power was bringing together Hardware Asset Management (HAM) and Software Asset Management (SAM) under one roof. No more separate systems or conflicting spreadsheets. Everything, including cloud-based assets that are increasingly vital, could be tracked and managed holistically. This gave us a truly comprehensive view of our technology footprint.

The Human Element and the Journey’s End

My journey through understanding and implementing ERP for our IT Asset Lifecycle taught me that it’s not just about the software itself; it’s about the shift in perspective it enables. It’s about moving from a reactive, chaotic approach to a proactive, strategic one. It’s about empowering IT teams with the information they need to do their jobs effectively, reducing their stress, and allowing them to focus on innovation rather than just chasing down inventory.

The days of guessing, frantic searches, and spreadsheet nightmares are largely behind us. With ERP, we gained clarity, control, and confidence in managing our vast and ever-evolving landscape of IT assets. It transformed a complex, often overwhelming task into a well-oiled, transparent process. If you’re still navigating the digital tangle with a blindfold on, take it from someone who’s been there: an ERP system, properly implemented, can be the compass and the map that guides you to a much clearer, more efficient future for your IT asset management. It certainly was for us.