I remember a time, not so long ago, when our warehouses felt less like organized hubs and more like giant, chaotic treasure hunts. Imagine a vast building, filled to the brim with boxes, pallets, and shelves stretching sky-high. Now, imagine needing to move a specific batch of widgets from one corner of that building to another, or even worse, from this building across town to our main distribution center. Sounds simple, right? It was anything but.

Back then, our system, if you could even call it that, was a tangled mess of spreadsheets, handwritten notes, and a whole lot of shouting across the floor. Someone would think they saw the widgets leave Warehouse A. Someone else would hope they’d arrive at Warehouse B. In between, there was a vast, dark chasm where goods could, and often did, simply vanish. Not literally, of course, but for all intents and purposes, they were lost to our inventory records. We’d have customers waiting, production lines halted, and our sales team tearing their hair out, all because we couldn’t tell them precisely where our stuff was.

It was a frustrating dance, a constant guessing game. We’d spend hours, sometimes days, chasing down inventory, recounting items, and trying to reconcile discrepancies that seemed to multiply faster than rabbits. This wasn’t just a minor inconvenience; it was costing us real money – in wasted time, delayed orders, and the sheer inefficiency of it all. Our stock numbers were always a mystery, and making any informed decision about what to order, what to sell, or how to fulfill an urgent request felt like throwing darts in the dark.

Then came the conversation about "ERP." To most of us on the floor, it sounded like another one of those fancy business acronyms that consultants love to throw around, promising miracles but delivering mountains of paperwork. But our management, bless their persistent hearts, saw a light at the end of our inventory tunnel. They talked about a comprehensive system that could link everything – sales, purchasing, production, and crucially for me, inventory and logistics. And within this grand scheme, they kept emphasizing a module called "Goods Transfer Tracking."

At first, I was skeptical. How could a piece of software solve the very human problem of things getting lost or misplaced? But as they laid out the vision, a glimmer of hope began to shine through the fog of my cynicism. The idea was simple: every single item, every pallet, every box that moved within our company, from one location to another, would be accounted for. No more guesswork, no more disappearing acts. It sounded like a dream, almost too good to be true.

So, what exactly is this ERP Goods Transfer Tracking that changed our world? In simple terms, it’s a digital diary, a detailed ledger, and a GPS for everything we own that needs to move. Imagine you have a book in your library. When you lend it to a friend, you write down who borrowed it, when, and when they promised to return it. If that friend then lends it to another friend, you update your record. ERP Goods Transfer Tracking does this, but for thousands of items, across multiple warehouses, production lines, and retail stores, all in real-time.

It’s the part of our Enterprise Resource Planning (ERP) system that specifically handles the movement of inventory between different internal locations. This isn’t about shipping something out to a customer; it’s about shifting stock from, say, our main warehouse to a smaller regional depot, or from a raw materials storage area to the production floor, or even from one aisle to another within the same warehouse. Before, these internal movements were our biggest blind spots. Now, they are some of our clearest.

The magic of it begins the moment someone decides an item needs to move. Let’s say our retail store in the city center runs low on a popular item. Historically, they’d call the main warehouse, and someone would jot down a note, maybe send an email. The item would be picked, thrown onto a truck, and eventually arrive. When? Nobody really knew until it showed up.

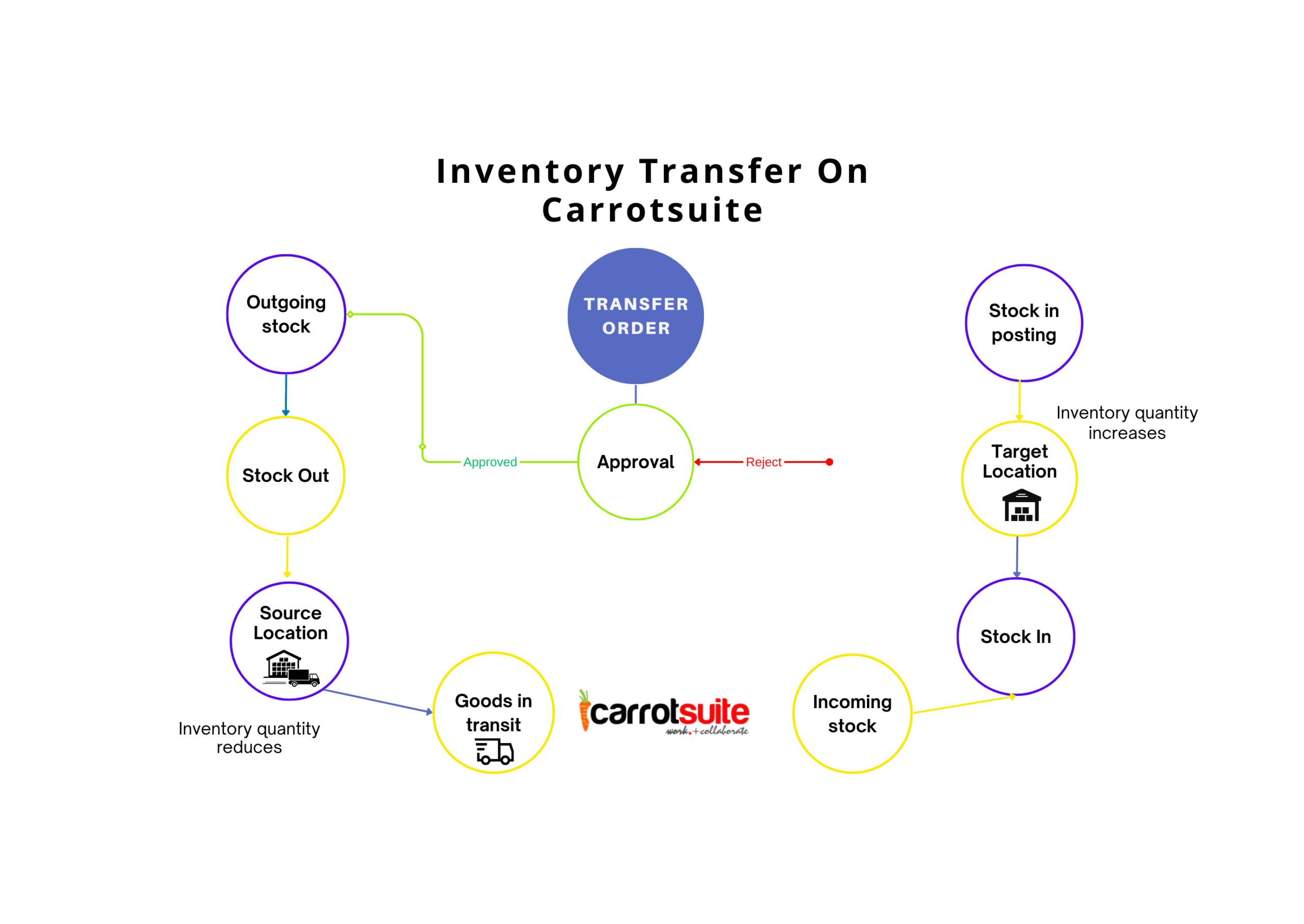

With ERP Goods Transfer Tracking, the process changed entirely. The store manager creates a "transfer request" directly in the system. They specify the item, the quantity, and the destination. This isn’t just a request; it’s the beginning of a digital paper trail. The system immediately checks if the item is available at the source warehouse. If it is, the request moves forward for approval, perhaps from a logistics manager or a stock controller.

Once approved, a "transfer order" is generated. This document isn’t just for printing; it’s a living record within the ERP. It tells the warehouse staff exactly what to pick and where to find it. They use handheld scanners, much like those you see at grocery checkouts, to confirm they’re picking the right items. Every scan updates the system. So, the moment an item is picked for transfer, our ERP knows it’s no longer sitting on a shelf in Warehouse A, but is now in a "picked" status, ready for transit.

Then comes the journey. When the items are loaded onto a truck, another scan confirms the departure. The system marks the items as "in-transit." This was a game-changer for us. Before, "in-transit" meant "who knows where it is?" Now, we could see, in our ERP system, that 20 units of that popular item were on their way from Warehouse A to the City Store, and they left at 10:30 AM. We could even link it to carrier tracking numbers if we were using a third-party logistics provider, though for internal transfers, the internal tracking was enough.

Finally, the items arrive at the City Store. The store staff uses their own scanner to "receive" the goods. This last scan is perhaps the most critical. It confirms that the items have arrived at their destination and are now officially part of the City Store’s inventory. Our system then automatically updates the stock levels: Warehouse A’s inventory goes down by 20 units, and the City Store’s inventory goes up by 20 units. All in real-time. No more manual counting, no more spreadsheets, no more frantic phone calls.

The impact of this shift was profound. For me, working in inventory, it felt like someone had handed me a pair of powerful binoculars after years of fumbling in the dark.

Visibility became our new superpower. I could open the ERP system at any moment and see exactly where every batch of goods was. If a customer called asking about an item, I could tell them, "Yes, we have 50 units arriving at our distribution center tomorrow morning," or "Those components are currently in transit from our supplier to our production plant." This wasn’t just about knowing where things were; it was about building trust with our customers and our internal teams. Everyone knew what was happening.

Accuracy went through the roof. Our inventory counts, which used to be notoriously unreliable, suddenly started matching reality. Because every movement was scanned and recorded, discrepancies became rare exceptions rather than the frustrating norm. When they did occur, we could trace back every step of the transfer process to find out where the mistake happened, rather than just shrugging our shoulders. This meant fewer stock-outs, less overstocking, and a much clearer picture of our actual assets. We stopped ordering things we already had but couldn’t find, saving us money and storage space.

Efficiency wasn’t just a buzzword anymore; it was our everyday reality. The hours we used to spend searching, reconciling, and correcting errors were freed up. Our warehouse staff could focus on their core tasks: picking, packing, and shipping, rather than playing detective. The transfer process itself became faster and more predictable. This meant goods moved through our internal supply chain more smoothly, reaching their destination quicker, which in turn meant happier customers and more efficient production cycles.

Better decision-making became second nature. With reliable, real-time data at our fingertips, our purchasing team could make smarter decisions about when and how much to order. Our sales team could promise delivery dates with confidence. Our production planners could schedule runs knowing the raw materials would be there when needed. It transformed our business from reactive and chaotic to proactive and organized. We could analyze transfer patterns, identify bottlenecks, and even predict future inventory needs with far greater accuracy.

Of course, it wasn’t an instant flip of a switch. Implementing ERP Goods Transfer Tracking was a journey, and like any journey, it had its bumps. There was the initial learning curve for everyone, especially those who were used to the old ways. Getting people to consistently scan everything, to trust the system, and to abandon their old notepads took patience and persistent training. We also had to ensure our master data – the details about each item, its weight, dimensions, and where it was stored – was accurate from the start. "Garbage in, garbage out" was a phrase we heard often, and it quickly taught us the importance of clean data.

There were moments of frustration, moments when a scanner wouldn’t connect, or someone forgot a crucial step. But what made the difference was the commitment from everyone to make it work. We saw the immediate benefits, the tangible improvements, and that motivated us to push through the challenges. We learned to troubleshoot together, to report issues, and to continuously refine our processes.

The beauty of it all is how it connects to the broader ERP landscape. A goods transfer isn’t just an isolated event; it has ripple effects throughout the company. When an item is transferred, our financial records are automatically updated. The value of inventory shifts from one cost center to another. Our sales team can see if an item they’re trying to sell is moving from a slow-moving warehouse to a high-demand retail outlet. It truly brings every part of the business onto the same page, speaking the same language of accurate, real-time data.

Looking back, the transition from our old, disjointed methods to a comprehensive ERP Goods Transfer Tracking system wasn’t just an upgrade; it was a revolution. It took us from a state of constant uncertainty and reactive firefighting to one of clarity, control, and foresight. Our warehouses are still vast, filled with boxes and pallets, but now they operate with a quiet hum of efficiency, guided by the precise, unwavering hand of our ERP system. The days of the chaotic treasure hunt are thankfully, and definitively, behind us. And that, I can tell you from personal experience, is a truly wonderful thing.