I remember a time, not so long ago, when our operations felt like a sprawling, overgrown garden. We had all the right plants – our Enterprise Resource Planning (ERP) system was robust, our teams were dedicated, and our intentions were good. But trying to figure out where things were, why they were stuck, or who was waiting on what felt like hacking through dense undergrowth with a dull machete. Every process, from ordering supplies to fulfilling customer requests, was a bit of a mystery once it left one person’s desk and moved to the next. We knew tasks were moving, or at least we hoped they were, but seeing the whole journey, understanding the detours, or even knowing if a crucial step was skipped entirely? That was a dream.

Our ERP system held all the data, every transaction, every status update. It was a treasure chest, but one without a map or a key. If a customer called asking about their order, we’d scramble. Someone would dig into the system, call another department, send an email, and eventually, after a lot of back-and-forth, piece together an answer. The same went for internal processes. Why was the monthly report late? Who was holding up the budget approval? The answers were always discovered after the problem had already caused a headache, sometimes a migraine. It wasn’t sustainable. We were constantly reacting to fires, big and small, instead of preventing them.

Then, a whisper started making its way through the office, a concept that sounded almost too good to be true: ERP workflow monitoring tools. At first, I was skeptical. Another tool? Another layer of complexity? We already had so much software. But the person who introduced the idea, our new operations lead, spoke with a conviction that caught my attention. She described a world where we could actually see our processes, where the journey of a task wasn’t a black box, but a brightly lit path. She talked about real-time visibility, identifying bottlenecks, and making data-driven decisions. It sounded like magic, or at least a significant upgrade from our current state of educated guesswork.

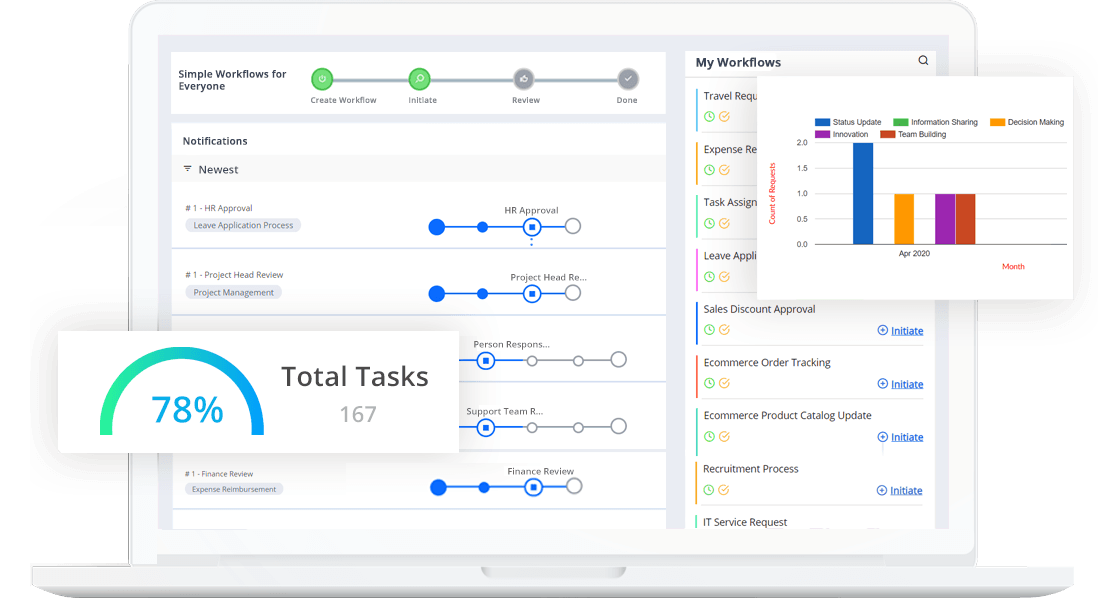

Our first step was to understand what these ERP workflow monitoring tools truly were. Stripping away the technical jargon, it boiled down to this: they are systems designed to watch the various steps of a business process as they unfold within your ERP environment. Think of it like a control tower for your business operations. Instead of just having the airplane take off and hoping it lands, you’d have a screen showing its exact location, speed, altitude, and any potential issues along the way. For us, this meant tracking purchase orders from creation to payment, sales orders from inquiry to delivery, or even internal approvals from submission to final sign-off.

The idea was compelling. We started looking into different solutions. It felt like walking into a massive hardware store without knowing exactly what kind of nail you needed. There were so many options, each promising to be the best. We learned about dashboards that show a high-level overview, alerts that notify you when something goes wrong or takes too long, and reporting features that let you analyze trends over time. The key, we realized, wasn’t just seeing the data, but seeing it contextually – understanding how each step connected to the next and how long each stage typically took.

Our pilot project was focused on our customer order fulfillment process. This was a particularly thorny area, often leading to customer complaints and frantic internal investigations. We selected an ERP workflow monitoring tool that promised relatively straightforward integration with our existing ERP system. The initial setup was a learning curve, no doubt about it. We had to define what each step of our order process looked like in the system, from when a sales representative created an order, to inventory allocation, warehouse picking, shipping, and finally, invoicing. It forced us to really think about our processes, to map them out in detail, which in itself was an incredibly valuable exercise.

What happened next felt transformative. Once the tool was up and running, it was like someone had flipped a switch and illuminated our entire operation. Suddenly, we had a central dashboard that showed every single customer order, where it was in its journey, and how long it had been there. No more frantic calls or emails. If an order was stuck in "inventory allocation" for an unusually long time, the dashboard flagged it. If a shipping notification wasn’t sent within the expected timeframe, we knew immediately.

I remember one specific instance vividly. An important customer called, concerned about a delayed shipment. In the past, this would have involved me calling the sales team, who would call the warehouse, who would then dig through their records. It would take hours. With the ERP workflow monitoring tool, I pulled up the order ID on the dashboard. It immediately showed that the order was packed and ready, but the shipping label hadn’t been generated due to a minor data entry error in the customer’s address. The system had even triggered an alert to the shipping department an hour earlier, but they hadn’t seen it yet amidst their other tasks. With that information in hand, I could instantly tell the customer exactly what the problem was, that it was being fixed, and when they could expect the shipment. It wasn’t just about fixing the problem; it was about the confidence and clarity I could provide.

This newfound visibility became our superpower. We started identifying bottlenecks we didn’t even know existed. For example, we discovered that a particular manager’s approval was consistently the longest step in our procurement process. It wasn’t because he was slow; it was because he was overwhelmed with other tasks and approvals were piling up on his digital desk. With this insight, we could address the root cause: we streamlined some approval thresholds and delegated certain types of purchases to other team members, freeing up his time and speeding up the entire process. Without the data provided by the ERP workflow monitoring tool, that bottleneck would have remained hidden, a constant drag on our efficiency.

The tools also brought a new level of proactivity. Instead of waiting for a customer to complain or a report to be late, we received alerts. These weren’t just simple "something is wrong" messages; they were contextual. "Order #12345 has been in the ‘picking’ stage for 3 hours longer than average." This allowed us to intervene before it became a major issue. We could reach out to the warehouse supervisor, understand the delay, and help them resolve it, often before anyone else even noticed. It was like having an early warning system that prevented small glitches from escalating into full-blown crises.

Beyond just fixing problems, these tools empowered us to truly optimize our operations. We started using the analytics and reporting features. We could see average processing times for each step, identify trends, and compare performance across different teams or time periods. This wasn’t just about blaming people; it was about understanding where our processes could be improved. We used the data to redesign workflows, automate repetitive steps, and even reallocate resources. For instance, by seeing that a particular data entry step was a frequent source of errors and delays, we invested in better training for that team and implemented stricter data validation rules within the ERP, drastically reducing rework.

One of the most profound impacts was on accountability and team morale. When everyone could see where a task stood, and who was responsible for the next step, there was a natural increase in ownership. No more "it’s not my job" or "I’m waiting on so-and-so." The dashboard provided an objective, shared truth. It fostered a collaborative environment where teams could identify dependencies and proactively communicate. Instead of silos, we started seeing interconnected departments working towards a common, visible goal. People felt more in control of their work, and the frustration of dealing with invisible delays significantly diminished.

Let me tell you a bit more about the specific features that became indispensable. The dashboards were our daily command center. We customized them to show what mattered most to each team – sales had their order fulfillment metrics, procurement had their purchase order statuses, and finance had their invoice approvals. These weren’t static reports; they were live, updating in real-time. It was like watching the pulse of our business.

Then there were the alerts and notifications. These were our digital watchdogs. We configured them for all sorts of scenarios: tasks exceeding a defined time limit, processes deviating from the standard path, or even critical milestones being missed. Some alerts went straight to the relevant team member via email or an in-app notification, others escalated to managers if the issue wasn’t resolved within a certain timeframe. It ensured that nothing critical slipped through the cracks.

The analytics and reporting capabilities were where we truly learned. We moved beyond just reacting and started predicting and improving. We could generate reports on process cycle times, identify bottlenecks by duration or frequency, analyze error rates at different stages, and even forecast future performance based on historical data. This transformed our monthly review meetings. Instead of discussing vague problems, we had concrete data points to analyze, leading to more productive discussions and actionable strategies. We could test changes to a workflow and immediately see the impact on efficiency metrics.

Another crucial aspect was process mapping and modeling. Some advanced ERP workflow monitoring tools allowed us to visually map out our processes within the tool itself. This wasn’t just a static diagram; it was a living representation that could be linked directly to the live data. We could simulate changes, identify potential failure points before they occurred, and even enforce certain rules to ensure compliance. It became a powerful tool for continuous improvement, allowing us to refine our operations with precision.

Of course, integration was key. For these ERP workflow monitoring tools to be truly effective, they needed to talk seamlessly with our existing ERP system. This was a critical factor in our selection process. We needed a tool that could pull data from our ERP without causing disruptions and, ideally, could push certain actions back into the ERP (like updating a status or triggering a notification). A good tool acts like a translator and conductor, orchestrating information flow without being a bottleneck itself.

The journey wasn’t without its bumps. There was initial resistance from some team members who felt like they were being watched or micromanaged. We had to emphasize that the goal wasn’t surveillance, but empowerment – to give everyone the tools to do their jobs better, identify systemic issues, and reduce individual stress. We focused on the positive outcomes: less firefighting, clearer expectations, and more efficient processes that benefited everyone. Data quality was another early hurdle. If the data going into the ERP was messy or incomplete, the monitoring tool would simply reflect that mess. It forced us to tighten up our data entry standards, which, while challenging initially, ultimately improved the reliability of all our systems.

Choosing the right ERP workflow monitoring tool also involved a lot of thought. We learned that what works for one company might not work for another. We considered several factors:

- Ease of Use: Could our team members, even those who weren’t tech-savvy, navigate the dashboards and understand the reports? A complex tool would sit unused.

- Integration Capabilities: How well did it connect with our specific ERP system? Was it a native integration, or would it require custom development?

- Scalability: Could it grow with us? As our company expanded and our processes evolved, would the tool still be able to handle the load and complexity?

- Reporting and Analytics: Did it offer the depth of insight we needed? Could we customize reports to answer our specific business questions?

- Alerting and Notification Features: Were the alerts configurable and actionable?

- Vendor Support and Training: What kind of support would we get during implementation and ongoing use?

- Cost: Of course, budget always played a role, but we quickly realized the return on investment from improved efficiency and reduced errors far outweighed the initial expense.

Looking back, the adoption of ERP workflow monitoring tools marked a pivotal moment for our company. We moved from a reactive, opaque operational model to a proactive, transparent one. The benefits were tangible: faster order fulfillment, reduced operational costs, fewer errors, and significantly improved customer satisfaction. Our teams were less stressed, more productive, and felt more connected to the overall business goals.