Remember those days? The ones where every department in the company felt like its own little island, complete with its own unique language, customs, and sometimes, even its own version of the truth. I certainly do. My name is Alex, and I’ve spent a good part of my career navigating the choppy waters of business operations. For years, our company, a bustling mid-sized manufacturing firm, was a masterclass in departmental silos. Each team, from sales to production, finance to HR, was doing its best, working hard, but often in isolation. It was like watching an orchestra where every musician played a different song, beautifully perhaps, but never quite in unison.

Sales would promise a delivery date without checking production’s schedule, leading to frantic calls and disappointed customers. Production would order raw materials based on historical data, only to find out Sales had just landed a massive new order that required different components, causing delays and wasted stock. Finance would be buried under a mountain of invoices and receipts, struggling to reconcile figures that didn’t quite match what Operations had recorded. And HR? They were constantly chasing paperwork, trying to onboard new employees while coordinating with IT for system access and with managers for equipment requests. It was a cycle of inefficiencies, miscommunications, and missed opportunities. We were growing, yes, but it felt like we were constantly fighting fires instead of building something solid.

The air was thick with "I didn’t know that," "Why wasn’t I informed?" and "That’s not my department." Information was fragmented, scattered across countless spreadsheets, email threads, and sometimes, even handwritten notes. Decisions were often made in a vacuum, based on incomplete data, and the right hand often had no idea what the left hand was doing. We were spending more time trying to coordinate efforts than actually making progress. The frustration was palpable, echoing through meeting rooms and spilling over into coffee breaks. It wasn’t that people weren’t trying; they were simply working within a system that didn’t allow for seamless interaction.

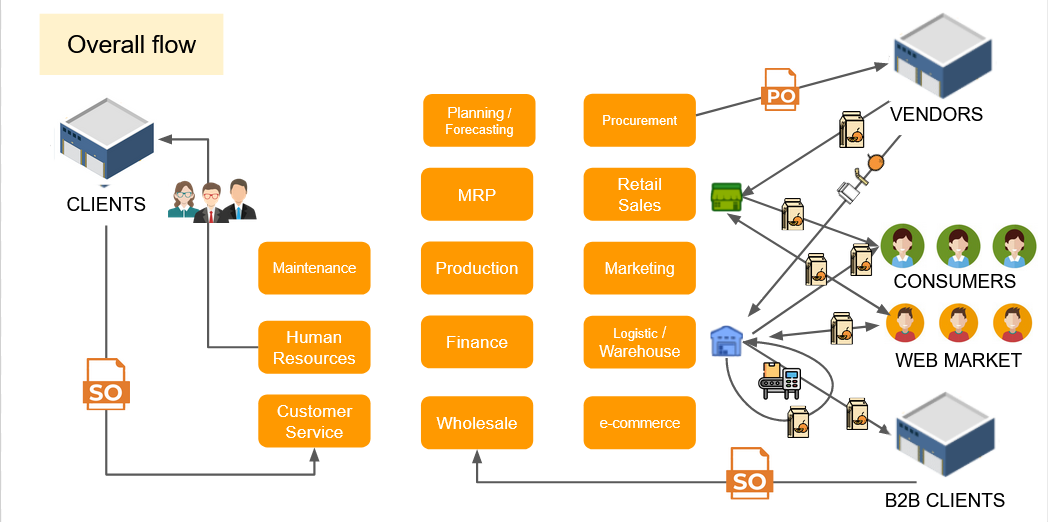

Then came the whispers, followed by serious discussions, about something called ERP – Enterprise Resource Planning. Honestly, at first, it sounded like another one of those fancy acronyms that promised the moon but delivered only more complexity. "Another system to learn?" many grumbled. "More data entry?" others sighed. I shared some of that skepticism. We had tried integrating a few tools before, with limited success. But the core idea behind ERP, as explained by our visionary (and somewhat exhausted) CEO, was different: a single, unified system that would connect all our departments, sharing information in real-time, creating a single source of truth for the entire company. It sounded like a pipe dream, but also, a desperately needed solution.

The implementation journey was, as expected, a rollercoaster. It wasn’t just about installing software; it was about fundamentally changing how we worked, how we thought about information, and how we interacted with each other. There were endless meetings, data migration headaches that made my eyes water, and training sessions that tested everyone’s patience. Old Frank in accounting, a man who swore by his ledger books, was convinced it was all a waste of time. "Computers can’t replace a good eye for detail, Alex," he’d tell me, shaking his head. But slowly, gradually, things began to shift.

My first "aha!" moment came a few months after going live. Our sales team had just closed a big deal. In the old days, that would trigger a flurry of emails: Sales to Production, Production to Purchasing, Purchasing to Warehouse, and then everyone to Finance for invoicing. Each step would have its own delay, its own potential for error. This time, however, I watched as the sales representative, Sarah, simply updated the deal status in the ERP. Almost instantly, a notification popped up for our production manager, Mark, detailing the order specifications. Mark, in turn, could see the current inventory levels of required raw materials, and if anything was short, the system flagged it for Purchasing. Finance, simultaneously, had access to the sales order and could begin preparing the invoice, linked directly to the customer’s profile. There were no frantic phone calls, no missing details. It was… smooth. It was like watching a perfectly choreographed dance where everyone knew their steps without needing to be told.

Let me tell you about the specific transformations I witnessed, department by department, and how ERP truly wove them together into a coherent whole.

Sales and Marketing: A United Front

Before ERP, our sales team often felt like they were flying blind. They’d generate leads, but tracking their journey through the pipeline was a manual, often inaccurate process. Marketing, meanwhile, would launch campaigns, but had little visibility into which ones truly converted into sales, or how those leads performed once they reached the sales team. With ERP, this changed dramatically.

Our marketing team could now feed leads directly into the system. Sales representatives could then access a complete history of each lead: what marketing materials they’d seen, what webinars they’d attended, what their initial inquiries were. This meant personalized follow-ups, not generic cold calls. When a lead became a customer, all that rich interaction data remained tied to their profile. Sales could see past orders, preferences, and any service issues. This integration wasn’t just about sharing contact details; it was about building a holistic view of every potential and existing customer. Sarah, our star salesperson, told me how much easier it was to build rapport when she could see, at a glance, that a customer had attended a specific product demo months ago. It made her conversations more relevant and ultimately, more successful.

Operations and Production: From Chaos to Precision

This was perhaps where the most immediate and tangible improvements were felt. Our manufacturing floor used to be a place of educated guesses. Production schedules were often disrupted by unexpected material shortages or sudden changes in sales orders. Inventory management was a constant struggle – too much of one thing, not enough of another, leading to wasted storage space or costly rush orders.

With ERP, our production team gained real-time visibility into incoming orders from Sales, current inventory levels, and even the status of raw materials from suppliers. Mark, our production manager, could now create schedules that were truly optimized. If a new order came in, he could instantly see its impact on existing schedules and material needs. The system could even suggest the most efficient production sequence, minimizing downtime and maximizing output. Our purchasing department, linked to inventory and production, could automate reorder points, ensuring we always had what we needed, but weren’t overstocking. This meant fewer delays, less waste, and a significant boost in our ability to meet customer demands reliably. I remember Mark beaming when he showed me a dashboard that displayed our factory’s output for the day, perfectly aligned with the sales forecast. "Alex," he said, "I finally feel like I’m driving, not just steering a boat in a storm."

Finance and Accounting: The End of Guesswork

Old Frank eventually came around. Our finance department, once perpetually swamped, found new breathing room. Before ERP, reconciling accounts was a monumental task. Sales data didn’t always match shipping data, which didn’t always match invoicing data. Discrepancies were common, leading to time-consuming investigations and delayed financial reporting.

ERP brought all financial transactions under one roof. Every sales order, every purchase order, every inventory movement, every payroll expense – it all flowed directly into the accounting modules. This meant real-time financial reporting. Our CFO could generate accurate profit and loss statements, balance sheets, and cash flow reports at the touch of a button, not weeks after the fact. Budgeting became more precise because we had a clearer, more immediate understanding of our actual spending. Invoicing was automated, linked directly to completed sales orders and shipments. Frank, to his credit, admitted that while he still loved his ledgers, the ERP made his job "a whole lot less headache-inducing." He found himself spending less time chasing numbers and more time analyzing them, offering valuable insights to the leadership team.

Human Resources and Payroll: Streamlined People Management

HR, often seen as an administrative function, also saw immense benefits. Onboarding new employees, managing benefits, tracking performance reviews, and processing payroll were all processes that required significant coordination across departments.

With ERP, an employee’s journey, from application to retirement, could be managed centrally. When a new hire joined, HR could initiate the onboarding process within the system. This automatically triggered requests to IT for system access, to their manager for equipment, and to payroll for setup. Performance reviews could be tracked, training modules assigned, and time-off requests managed, all within the integrated environment. This didn’t just save HR countless hours; it created a much smoother, more welcoming experience for new employees and ensured compliance across the board. Our HR manager, Maria, told me it felt like she could finally focus on "people development" rather than just "paper pushing."

Customer Service: A Unified View of the Customer

Perhaps one of the most impactful changes was in our customer service department. Previously, when a customer called with an issue, our service representatives would often have to juggle multiple systems, or make calls to different departments, just to piece together their history. "Let me check with shipping," or "I’ll have to call accounting for that," were common refrains. This led to frustratingly long call times and often, dissatisfied customers.

With ERP, our customer service team gained instant access to a complete 360-degree view of every customer. They could see past orders, payment history, shipping status, previous service interactions, and even notes from the sales team. If a customer called about a delayed order, the representative could instantly see where the order was in the production cycle, or if it had shipped. If they called about an invoice, they could access it directly. This empowered our service team to resolve issues quickly and effectively, often on the first call. It transformed our customer service from reactive problem-solving to proactive relationship building. Our customers noticed, and our customer satisfaction scores climbed steadily.

The Unseen Backbone: IT and Data Integrity

Behind all these visible improvements was our IT department, ensuring the ERP system ran smoothly, securely, and with accurate data. With a single, integrated system, the nightmare of disparate databases and conflicting information became a thing of the past. Data was entered once and accessible everywhere, greatly reducing errors and ensuring consistency. This "single source of truth" was fundamental. It meant that everyone, from the CEO to the front-line employee, was looking at the same numbers, operating with the same facts. This fostered trust and vastly improved the quality of our decision-making.

Beyond Efficiency: The Ripple Effect of Collaboration

The benefits of this multi-department collaboration went far beyond mere efficiency. It fostered a culture of transparency and shared responsibility. When everyone could see how their work impacted the next step in the process, and ultimately, the customer, it created a stronger sense of purpose and accountability.

- Improved Communication: The system itself became the primary communication channel for operational data. Less email clutter, fewer missed messages.

- Enhanced Data Accuracy: With data entered once and shared across departments, the chances of errors were significantly reduced.