I remember it like it was yesterday, the sheer chaos of our old procurement process. Before we embraced the power of an ERP system, our company’s purchasing was a tangled web of paper, phone calls, and desperate email searches. It felt less like a well-oiled machine and more like a scavenger hunt where the prize was sometimes the wrong item, delivered late, to the wrong department. We’d have requisitions scribbled on sticky notes, approval forms that seemed to vanish into thin air, and invoices that appeared out of nowhere, often for goods we couldn’t even confirm we’d received. The stress was palpable, not just for the purchasing team, but for everyone who depended on getting the right supplies at the right time. That’s where our journey with the ERP Purchase Order Workflow began, a journey that truly revolutionized how we did business.

When we first started talking about implementing an Enterprise Resource Planning, or ERP, system, I’ll admit I was skeptical. It sounded like another fancy piece of software that would promise the moon but deliver only more headaches. But our leadership was determined, seeing the bottlenecks in our supply chain and the money we were losing to inefficiencies. They painted a picture of a seamless, automated process, a single source of truth for all our operations, and honestly, it sounded a bit like magic. The area they focused on first, and arguably the one that saw the most dramatic change, was our purchase order workflow.

To understand the magic, you first need to grasp what a Purchase Order (PO) is. Simply put, it’s a legally binding document issued by a buyer to a seller, indicating types, quantities, and agreed prices for products or services the seller will provide to the buyer. It’s the official request, the commitment to buy. Before ERP, creating these was an art form in itself, often involving manual data entry, cross-referencing price lists, and hoping you typed the vendor’s address correctly for the tenth time that day.

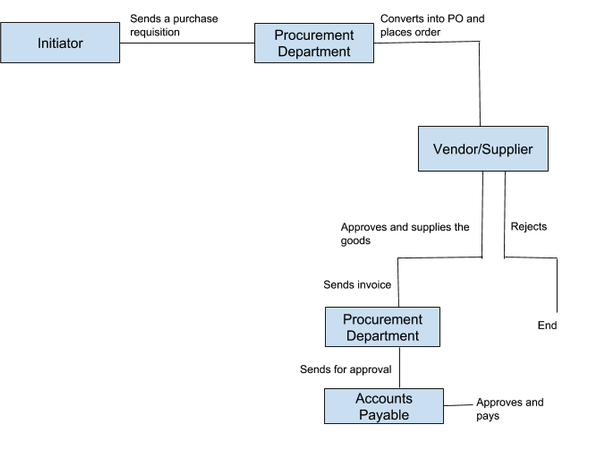

Our ERP, once implemented, became the central nervous system for our procurement. It took a chaotic, multi-step dance and choreographed it into a smooth, logical sequence, all within a single digital environment. Let me walk you through how our ERP Purchase Order Workflow now unfolds, step by step, from the moment someone realizes they need something, to the final payment.

The first step in our new, streamlined process is what we call the Purchase Requisition. Think of it as the initial spark, the "I need this!" moment. Before ERP, this was often an email, a phone call, or, as I mentioned, a sticky note. Now, anyone in the company who needs to purchase something, be it office supplies, raw materials for production, or a new piece of software, logs into the ERP system. They fill out a digital form – easy to use, with pre-filled fields for common items and clear prompts for new ones. They specify what they need, the quantity, when they need it, and, importantly, why. This justification, which used to be an afterthought or a quick chat, is now a mandatory field, ensuring everyone thinks critically about their requests. The system automatically pulls details like the requestor’s department and budget code, reducing errors right from the start. This digital requisition is then ready for its journey.

Next comes the crucial stage: Approval. This was perhaps the biggest headache in our pre-ERP days. A requisition for a new monitor might need approval from a department head, then a budget manager, and sometimes even IT. Papers would get lost on desks, emails would be missed, and people would be out of the office, bringing everything to a grinding halt. With ERP, the approval process became automated and intelligent. Once a requisition is submitted, the system automatically routes it to the appropriate approver or sequence of approvers based on predefined rules. For example, a small office supply order might only need a single manager’s approval, while a large capital expenditure would go through multiple layers, including finance and even senior leadership. Approvers receive instant notifications, and they can review all the details – the item, the cost, the justification, the budget impact – right there in the system, even from their mobile device. They can approve, reject, or ask for more information with a click, and the system keeps a detailed audit trail of every decision. No more lost papers, no more chasing people down. The progress of the requisition is transparent to everyone involved. I remember the relief when I first saw how quickly approvals started flowing; it was like clearing a dam.

Once a requisition is approved, it’s time to create the Purchase Order (PO) itself. This is where the approved request transforms into an official commitment to a vendor. In the old days, a purchasing agent would manually transcribe the approved requisition details onto a PO form, often having to look up vendor information, pricing, and terms from separate spreadsheets or even physical catalogs. This was ripe for errors – wrong quantities, outdated prices, or even ordering from the wrong supplier. Our ERP changed all that. The system automatically converts the approved requisition into a draft PO, pre-populating all the necessary information. It pulls vendor details, agreed-upon pricing, and payment terms directly from our vendor master data, ensuring consistency and accuracy. If we have existing contracts or preferred supplier agreements, the system flags these, ensuring we always get the best deal and adhere to our purchasing policies. The purchasing team reviews the draft, makes any final adjustments, and then, with another click, the PO is generated. It’s a standardized, professional document, ready to be sent.

Sending the PO to the vendor is the next logical step. Our ERP seamlessly handles PO Transmission. Instead of printing, faxing, or manually emailing, the system can automatically send the PO to the vendor via email, often as a PDF attachment. For our larger, more integrated suppliers, we even use Electronic Data Interchange (EDI), where the PO goes directly from our ERP to their system, minimizing manual intervention on both sides. The system also records when the PO was sent and provides a tracking number, so we always know its status. No more wondering if the vendor ever received our order. This automation drastically cut down on lead times and improved our vendor relationships because they received clear, accurate orders promptly.

Then comes the exciting part: Goods Receipt. This is when the ordered items physically arrive at our warehouse or office. Before ERP, this process was often messy. Someone in receiving would sign for a delivery, maybe make a note on a packing slip, and then that slip would eventually make its way to accounts payable. Often, it was hard to tell if the received items matched an actual PO or if they were even the correct quantity. With ERP, when a delivery arrives, our receiving team accesses the system, looks up the relevant Purchase Order, and records the incoming goods. They can confirm the quantity received, note any damages, and even record partial deliveries. The system generates a Goods Receipt Note (GRN), which is electronically linked back to the original Purchase Order. This immediate update in the system means our inventory levels are accurate in real-time, and anyone in the company can see that the items have arrived. This visibility was a huge win, especially for production planning and project managers who needed to know exactly when their materials would be available.

The financial heart of the purchase order workflow lies in Invoice Matching. This step is critical for ensuring we only pay for what we ordered and received. In the old days, our accounts payable team would receive an invoice from a vendor and then embark on a detective mission. They’d hunt down the original PO, search for the delivery note or packing slip, and try to manually reconcile the three documents – the PO, the GRN (or delivery note), and the vendor invoice. Discrepancies were common, leading to delays, disputes with vendors, and sometimes, even overpayments. With our ERP, this process is largely automated. When a vendor invoice comes in, it’s entered into the system (or even automatically imported if we’re using electronic invoicing). The ERP then performs a crucial "3-way match": it compares the invoice against the original Purchase Order and the Goods Receipt Note. It checks if the quantity invoiced matches the quantity ordered and received, and if the price matches the agreed-upon price on the PO. If everything aligns, the invoice is automatically approved for payment. If there’s a discrepancy – say, the vendor invoiced for more than we received, or at a higher price – the system flags it immediately. It then routes the discrepancy to the appropriate person (e.g., the purchasing agent or the receiving manager) for resolution. This eliminated countless hours of manual reconciliation, drastically reduced errors, and significantly strengthened our financial controls, preventing fraudulent or incorrect payments.

Finally, we reach Payment Processing. Once an invoice has been successfully matched and approved, it moves into the payment queue within the ERP’s financial module. Our ERP integrates seamlessly with our banking systems, allowing for automated payment runs. Based on the payment terms agreed upon in the original PO, the system schedules and executes payments to vendors. This could be via electronic funds transfer (EFT), ACH, or even generating checks, all within the ERP. The system also records the payment, closing the loop on that specific purchase order. This ensures timely payments, which is vital for maintaining good relationships with our suppliers and often allows us to take advantage of early payment discounts. It also provides a complete audit trail, from the initial requisition to the final payment, all within one system.

Beyond these sequential steps, the true power of our ERP Purchase Order Workflow lies in the overarching benefits it brought to our entire organization.

One of the most immediate and tangible benefits was Efficiency and Time Savings. I used to see purchasing agents drowning in paperwork, spending hours just tracking down information. Now, they spend their time on more strategic tasks, like vendor negotiation, market analysis, and identifying cost-saving opportunities. The automation of routine tasks, from requisition routing to invoice matching, freed up countless hours across multiple departments.

Then there’s Cost Savings. By centralizing vendor information and pricing, and by enforcing purchasing policies through automated approvals, we gained better control over our spending. The ERP helped us identify opportunities for bulk purchasing, consolidate suppliers, and ensure we always honored our contractual pricing. The 3-way matching process virtually eliminated overpayments and duplicate invoices, directly impacting our bottom line.

Enhanced Visibility and Data for Decision-Making became a game-changer. With all purchasing data residing in one system, our management gained unprecedented insights. We could easily generate reports on spending by department, by vendor, by product category. We could track lead times, vendor performance, and budget adherence in real-time. This data empowered us to make informed decisions, optimize our supply chain, and forecast future needs with much greater accuracy. No more guessing games; we had the facts at our fingertips.

Improved Compliance and Audit Trails were also incredibly important. Every action, every approval, every change within the ERP workflow is recorded and timestamped. This created an immutable audit trail, making it incredibly easy to demonstrate compliance with internal policies and external regulations. When auditors came calling, we no longer had to scramble to gather disparate documents; all the information was neatly organized and accessible within the system.

Finally, Better Vendor Relationships emerged as a surprising but welcome outcome. With clear, accurate purchase orders, timely payments, and streamlined communication, our interactions with suppliers became smoother and more professional. This fosters trust and often leads to better terms and service from our partners.

Of course, the journey wasn’t without its challenges. Implementing an ERP system is a significant undertaking. It required a substantial investment in time, money, and most importantly, a commitment to change from everyone. There were training hurdles, initial resistance to new ways of working, and the inevitable data migration headaches. But looking back, every single one of those challenges was worth overcoming.

My biggest takeaway from this whole experience is that an ERP Purchase Order Workflow isn’t just about software; it’s about transforming a fundamental business process. It’s about moving from reactive, chaotic purchasing to proactive, strategic procurement. It’s about empowering employees with tools that make their jobs easier and more impactful. It’s about gaining control, reducing risk, and ultimately, contributing directly to the company’s financial health and operational excellence.

If you had told me years ago, when I was sifting through piles of invoices and chasing down signatures, that one day our entire purchasing process would run with such precision and transparency, I would have laughed. But here we are, and it’s no longer magic. It’s simply the power of a well-implemented ERP system, guiding our purchase orders from the spark of a need to the final payment, every single time. And that, my friends, is a story worth telling.