I remember a time, not so long ago, when our distribution center felt less like a well-oiled machine and more like a perpetually surprised octopus, flailing its arms in a desperate attempt to grab everything at once. Orders would pour in, emails would ping, phones would ring off the hook, and we’d be scrambling. It was a chaotic symphony of shouting, hurried footsteps, and the constant fear of forgetting something crucial. We were good people, hardworking people, but we were using tools that belonged in a museum, or at least a much smaller operation. Our "planning" was essentially a mix of gut feelings, a heavily annotated whiteboard, and a collection of spreadsheets that would make even the most seasoned data analyst weep.

Back then, managing inventory felt like a high-stakes guessing game. We’d order too much of one item, and it would sit in the warehouse, collecting dust and eating up valuable space, tying up capital we desperately needed elsewhere. Then, just as predictably, we’d run out of another, critical item, leading to backorders, frustrated customers, and hurried, expensive rush shipments. It wasn’t just about the stock itself; it was about the ripple effect. A delayed component meant a delayed production line, which meant a delayed finished product, and ultimately, a missed delivery date. The complaints would pile up, and our reputation, which we’d worked so hard to build, felt like it was constantly under siege.

Our transportation planning was equally… primitive. We’d try to consolidate shipments, but often it was a matter of fitting as much as possible onto the next available truck, regardless of the most efficient route. Fuel costs were always a concern, but the complexity of manually mapping out optimal paths for dozens of deliveries a day, factoring in traffic, delivery windows, and truck capacities, was simply overwhelming. We’d often send out half-empty trucks or make unnecessary detours, simply because we lacked the overarching visibility to do better. Every day felt like putting out fires, and the long-term strategic vision was lost in the smoke.

Then came the conversation about "ERP Distribution Planning Tools." At first, it sounded like another layer of jargon, another expensive piece of software that would promise the world and deliver a complex manual. But our leadership, tired of the constant firefighting, insisted we look into it seriously. What I quickly learned, through countless demonstrations and discussions, was that these weren’t just fancy spreadsheets; they were comprehensive systems designed to bring order to the chaos, to turn our octopus into a graceful ballet dancer.

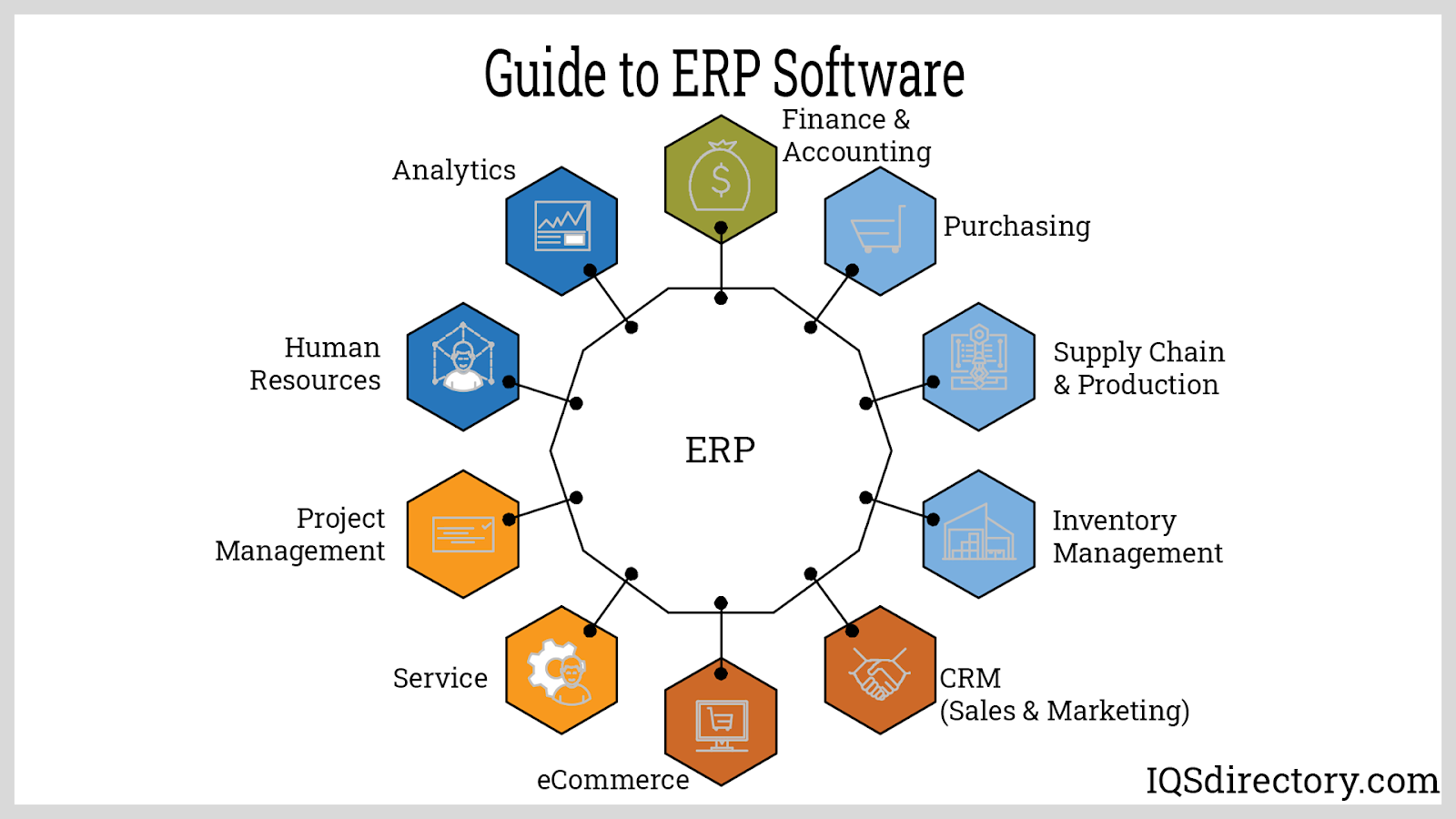

The core idea, I came to understand, was to integrate all aspects of our distribution process into a single, cohesive system. No more isolated silos of information. No more departmental guesswork. Everything from forecasting demand to managing inventory, optimizing warehouse operations, and planning transportation would be connected. It was like finally getting a single, master conductor for our chaotic orchestra.

One of the first revelations was how these tools revolutionized our inventory management. Before, we relied on historical sales data, sure, but it was often static, hard to update quickly, and didn’t really account for seasonal shifts, promotions, or sudden market trends. With an ERP system, we started seeing things differently. It wasn’t just about what we sold last month; it was about analyzing patterns, understanding lead times from suppliers, and calculating optimal reorder points. The system would use sophisticated algorithms to forecast demand, taking into account a myriad of factors that we simply couldn’t juggle manually. We could set parameters for safety stock, ensuring we always had enough critical items without overstocking non-essentials. Suddenly, the shelves were leaner, but full of the right products. We freed up capital, reduced spoilage, and most importantly, drastically cut down on those dreaded stock-outs. The feeling of seeing an order come in and knowing, with certainty, that the item was in stock and ready to ship, was genuinely exhilarating.

Then there was the magic of warehouse management. Our old warehouse system was, well, it was our warehouse manager, bless his cotton socks, and his encyclopedic knowledge of where everything should be. But when he was out, or when new staff came in, finding anything was a treasure hunt. With an ERP’s integrated warehouse management module, everything changed. Items were assigned specific locations, optimized for picking efficiency. The system guided pickers along the most efficient routes, minimizing travel time and errors. Receiving goods became a streamlined process, with items scanned, verified, and directed to their proper place almost instantly. What’s more, the system provided real-time visibility into every item’s location and status. No more wondering if a product had arrived, or if it was still in transit, or if it was sitting on a pallet in the back corner. We knew. And knowing, in distribution, is power.

The impact on order fulfillment was immediate and profound. Imagine the difference between manually transcribing orders, checking stock levels by walking to a shelf, and then manually creating shipping labels, versus a system where an order comes in digitally, stock is automatically verified, picking instructions are sent to a mobile device, and shipping labels are generated with a click. It wasn’t just faster; it was far more accurate. Fewer picking errors meant fewer returns, fewer reshipments, and happier customers. The entire process, from the moment an order was placed to the moment it left our dock, became a seamless, traceable journey. Our customer service team, once bogged down with "where’s my order?" calls, could now give precise updates, because the information was right there, at their fingertips.

But perhaps the biggest game-changer for me, personally, was in logistics and transportation planning. This was where the octopus truly transformed into a ballet dancer. Before, our routing was a nightmare. We’d have a general idea of delivery zones, but optimizing routes for multiple trucks, considering traffic, driver availability, vehicle capacity, and specific delivery windows, was a mental Herculean task. Our ERP system introduced us to route optimization. It wasn’t just about finding the shortest path; it was about finding the most efficient path. It would factor in all those variables, even real-time traffic updates, to create routes that minimized fuel consumption, driving time, and ultimately, delivery costs. We could consolidate shipments more effectively, ensuring trucks were loaded to capacity. We could track our fleet in real-time, anticipate delays, and communicate proactively with customers. This wasn’t just about saving money; it was about making our deliveries predictable, reliable, and professional.

The beauty of these tools, I realized, wasn’t just in their individual capabilities, but in their interconnectedness. This real-time visibility across the entire supply chain was revolutionary. From the moment a supplier confirmed a shipment to us, to the moment our truck delivered it to a customer, every step was trackable. We could see potential bottlenecks forming before they became crises. We could react to unexpected disruptions – a sudden road closure, a supplier delay, a surge in demand – with agility, rather than being caught flat-footed. This proactive approach replaced our old reactive, crisis-management style.

Of course, implementing an ERP system wasn’t a walk in the park. It was a massive undertaking, requiring significant investment in both time and money. There were endless meetings, data migration challenges that made us want to pull our hair out, and the inevitable resistance to change from some of the team members who were comfortable with the old ways. We had to clean up years of messy data, standardize processes, and learn entirely new ways of working. There were moments of frustration, moments where we wondered if we’d made the right decision. But through it all, the promise of a more efficient, more profitable future kept us pushing forward.

What truly struck me was how these tools fostered operational efficiency and cost reduction. We saw direct savings in fuel, reduced inventory holding costs, and fewer errors that required expensive fixes. But beyond the direct financial benefits, there was an intangible gain: the reduction in stress. The constant pressure of uncertainty began to lift. Our teams, once frazzled and overworked, could now focus on value-added tasks rather than just chasing down information or fixing preventable mistakes. This led to higher employee morale and a more productive work environment.

And the impact on customer satisfaction? Immeasurable. When customers receive their orders on time, accurately, and with clear communication, they’re happy. Happy customers become repeat customers. They recommend you to others. Our customer service metrics improved dramatically. The number of complaints plummeted, while positive feedback soared. We were no longer just a vendor; we were a reliable partner.

Looking back, the journey from chaos to control, from guesswork to data-driven decisions, was powered by these ERP distribution planning tools. They aren’t just software; they are strategic assets that enable businesses to not only survive but thrive in an increasingly complex and competitive global marketplace. They provide the backbone for a resilient supply chain, allowing companies to adapt quickly to market changes, manage risks effectively, and consistently deliver on their promises.

For anyone still wrestling with spreadsheets and gut feelings in their distribution operations, my advice is simple: explore the world of ERP. It’s an investment, yes, but it’s an investment in clarity, efficiency, and growth. It’s about transforming your perpetually surprised octopus into a graceful, powerful engine that propels your business forward. It certainly did for ours, and the difference, I can tell you from personal experience, is nothing short of transformative. We went from simply fulfilling orders to strategically orchestrating our entire distribution network, and that, for a storyteller like me, is a tale worth telling.