I remember the days when managing our fleet felt like a never-ending game of whack-a-mole. Every morning brought a new surprise: a truck refusing to start, a flat tire on a delivery run, or worse, a major engine problem that left us scrambling. We ran a modest operation, a fleet of about thirty vehicles – delivery vans, a few heavy-duty trucks, and some specialized equipment. Each one was a lifeline for our business, and every breakdown was a hit to our bottom line and our reputation.

Our maintenance system, if you could even call it that, was a chaotic mix of handwritten notes, crumpled service records stuffed into glove compartments, and an increasingly bloated spreadsheet that only one person (me, naturally) truly understood. When a truck needed an oil change, we’d try to remember the last time it had one, or guess based on mileage. Parts inventory was a nightmare; we’d often buy more of something we already had, or run out of a common filter just when we needed it most, leading to frustrating delays. Mechanics spent more time tracking down information or waiting for parts than they did actually fixing things. Our fuel bills were always high, but we had no real way to pinpoint why or where the inefficiencies were. It was a constant cycle of reacting to problems, putting out fires, and hoping for the best.

The stress was immense. I’d lie awake at night thinking about what could go wrong tomorrow. Our vehicles were aging faster than they should, our operational costs were climbing, and our drivers, bless their hearts, were growing increasingly frustrated with unreliable equipment. I knew we needed a change, a big one. That’s when I first heard whispers about ERP Fleet Maintenance Solutions. Honestly, it sounded like something for huge corporations with hundreds of vehicles and unlimited budgets. But the more I looked into it, the more I realized it wasn’t just fancy software; it was a different way of thinking about fleet management, a chance to bring order to our daily chaos.

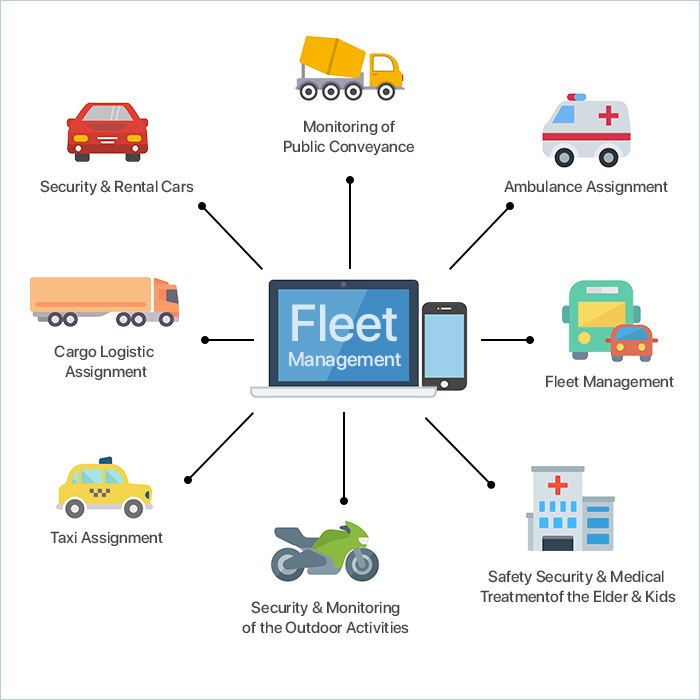

At its heart, an ERP (Enterprise Resource Planning) system, when applied to fleet maintenance, is like giving your entire vehicle operation a central brain. Instead of scattered information and disconnected tasks, everything comes together in one place. Imagine having a single, clear picture of every vehicle, every part, every mechanic, and every maintenance task, all updated in real-time. That’s the promise of an ERP Fleet Maintenance Solution. It’s about moving from guessing and reacting to knowing and planning.

My journey began with a lot of research and talking to other fleet managers. I was trying to understand how this “central brain” actually worked for a fleet like ours. What I learned was that it’s made up of several key parts, or modules, that work together smoothly. Let me tell you about the ones that made the biggest difference for us.

The first and most fundamental piece was Vehicle and Asset Management. Before the ERP, keeping track of each vehicle’s life story was a mess. We had purchase dates, warranty info, license plate numbers, and vehicle identification numbers (VINs) scattered across various files. With the ERP, we created a digital profile for every single asset, not just our trucks and vans, but also our forklifts and specialized tools. Each profile held everything: make, model, year, purchase details, depreciation schedules, insurance policies, and even the last time it was inspected. It was like giving each vehicle its own digital passport and diary, all in one accessible place. This meant that at any moment, I could pull up a truck’s complete history – not just its service records, but its financial standing and compliance details too. It took away a lot of guesswork and made sure we never missed an important renewal or inspection again.

But the real game-changer, the one that truly transformed our operations, was the Maintenance Scheduling module. This is where we moved from reactive repairs to proactive care. In the old days, a truck broke down, and then we fixed it. It was expensive, caused delays, and was honestly quite dangerous sometimes. With the ERP, we could set up detailed preventive maintenance schedules based on mileage, engine hours, calendar dates, or even specific sensor readings. So, instead of waiting for a truck to sputter, we’d get an automatic alert that Truck #12 was due for an oil change at 10,000 miles, or that the brakes on Van #5 needed checking every six months.

This meant our mechanics could plan their work instead of constantly being pulled into emergency fixes. They knew what was coming, could order parts ahead of time, and schedule their bays more efficiently. We also started exploring predictive maintenance, which is like preventive maintenance but even smarter. By linking our vehicles with some simple telematics devices, the system could pick up on early warning signs – a slight drop in engine pressure, an unusual vibration. It wasn’t always perfect, but it gave us a heads-up that something might go wrong soon, allowing us to investigate and fix it before it became a major, costly breakdown. This shift alone saved us countless hours of downtime and a significant amount of money on emergency repairs and towing services. Our vehicles lasted longer, too, because they were getting the attention they needed, when they needed it.

Then there was Parts and Inventory Management. Oh, the relief! Our storage room used to be a jumble of boxes, some labeled, some not. We’d often find ourselves with too much of one thing and none of another. With the ERP, every single spare part was cataloged, given a unique identifier, and tracked. When a mechanic needed a specific filter for a repair, they could check the system to see if it was in stock, where it was located, and even if it was already allocated for another job. The system automatically tracked parts used and updated inventory levels. We set up minimum stock levels, so when we dipped below a certain number of air filters, the system would automatically suggest an order, or even place one with our preferred supplier. This meant we always had the right parts on hand, reducing repair times and cutting down on unnecessary emergency purchases. It also gave us a clear picture of what parts were costing us the most, helping us negotiate better deals with suppliers.

Managing our mechanics and their workspace became much easier with the Workshop Management module. Before, work orders were often handwritten, sometimes misplaced, and tracking mechanic hours was a manual process. With the ERP, work orders were created digitally, assigned to specific mechanics, and tracked from start to finish. Mechanics could log their time directly into the system for each task, giving us a precise record of labor costs per job. We could see which mechanic was working on what, which bays were occupied, and even estimate job completion times more accurately. This transparency helped us manage our team better, identify training needs, and ensure everyone was being productive. It made our workshop a much more organized and less frantic place.

Fuel Management was another area where we saw big improvements. Fuel is a huge expense for any fleet, and we always felt like we were throwing money into a black hole. By integrating our fuel cards and telemetry data into the ERP, we could track every drop of fuel. The system would tell us not just how much fuel each vehicle consumed, but also its average miles per gallon, and even flag unusual spikes in consumption that might indicate a problem with the vehicle or a driving habit that needed addressing. We could compare fuel efficiency across different vehicles and drivers, helping us make better decisions about vehicle purchasing and driver training. It wasn’t just about saving money; it was about understanding one of our biggest operational costs in a way we never could before.

Finally, the Compliance and Reporting module brought a sense of calm to a previously stressful area. Regulatory compliance for fleets can be a minefield of deadlines and paperwork. With the ERP, we could store all our vehicle registrations, insurance documents, driver licenses, and inspection certificates in one place, with automated reminders for renewals. When it came time for a DOT inspection or an emissions check, all the necessary records were just a few clicks away. Beyond compliance, the reporting features were invaluable. I could generate reports on anything: vehicle downtime, maintenance costs per vehicle, fuel efficiency trends, parts usage, mechanic productivity. This data allowed us to make truly informed decisions, rather than relying on gut feelings. We could see which vehicles were costing us the most to maintain, helping us decide when to repair or replace them. We could identify areas where our operations could be tighter and more efficient.

Of course, getting to this point wasn’t an overnight miracle. Implementing the ERP was a significant undertaking. It involved careful planning, a lot of data entry to get all our existing information into the new system, and, perhaps most importantly, training our team. There was some initial resistance, as there always is with change. Some mechanics were used to their old ways, and the idea of logging everything into a computer felt like extra work. But we made sure to explain the "why" behind it, showing them how it would make their jobs easier in the long run – no more hunting for parts, clear work instructions, less emergency stress. We had dedicated training sessions, provided ongoing support, and celebrated small victories along the way. Gradually, everyone started to see the benefits, and the system became a natural part of our daily routine.

The “aha!” moments started happening more frequently. I remember one instance when a truck had a persistent electrical issue that our mechanics had been chasing for weeks. With the ERP, we could pull up every repair record for that specific truck, going back years. We noticed a pattern: several seemingly unrelated electrical problems that had been fixed individually. The ERP’s detailed history allowed us to see the bigger picture, helping us diagnose a systemic wiring problem that had been missed before. We fixed it properly, and that truck has been running smoothly ever since. That was a moment when I truly understood the power of having all that information connected.

Our fleet transformed. Breakdowns became rare instead of routine. Our maintenance costs dropped by a noticeable margin because we were doing preventive work and making smarter parts purchases. Our fuel efficiency improved because we could identify and address issues. Our vehicles lasted longer, which meant we weren’t replacing them as frequently, saving us a huge amount of capital. Our drivers were happier because their trucks were reliable and safe. And for me, the stress of fleet management was replaced with a sense of control and clarity. I could finally see what was happening across our entire operation, make informed choices, and focus on growing the business rather than constantly putting out fires.

Looking ahead, the journey with ERP Fleet Maintenance continues to evolve. We’re now exploring how to integrate even more real-time data from our vehicles – things like tire pressure monitoring, engine diagnostics straight from the vehicle’s computer, and even driver behavior analytics. The idea is to move towards an even more predictive model, where the system can tell us not just what will happen, but also suggest the best course of action. It’s about using every piece of information to keep our fleet running as smoothly and efficiently as possible.

If you’re wrestling with the chaos of fleet management, if your maintenance costs are spiraling, and if you’re tired of the constant surprises, I truly believe an ERP Fleet Maintenance Solution is worth exploring. It’s not just a piece of software; it’s an investment in the health of your fleet, the efficiency of your operations, and ultimately, the peace of mind for everyone involved. It changed our story from one of constant struggle to one of steady progress and improved reliability. And that, in my book, is a win.