Hello there! Let me tell you a story. It’s a story about a time when I used to stare at our factory floor, feeling a knot in my stomach. Machines, big, expensive machines, stood idle more often than they hummed. Some were overworked, others barely touched. We were pouring money into them, but I had no real idea if we were getting our money’s worth. It was like trying to navigate a dense fog with a blindfold on – frustrating, inefficient, and frankly, a bit scary for the bottom line.

That’s where my journey into the world of ERP Equipment Utilization Tracking began. And let me tell you, it was a game-changer. If you’re a business owner, a manager, or just someone curious about how to squeeze more efficiency out of your valuable assets, pull up a chair. This is for you.

What Even Is ERP Equipment Utilization Tracking? (Let’s Break It Down Simply)

Before we dive into my personal "aha!" moments, let’s get the jargon out of the way.

ERP stands for Enterprise Resource Planning. Think of it as the central nervous system of your business. It’s a software system that integrates all the different functions of your company – from finance and HR to manufacturing and supply chain – into one cohesive system. It helps everything talk to everything else.

Now, Equipment Utilization Tracking. This is precisely what it sounds like: keeping tabs on how much and how well your equipment is being used. Are your machines running? For how long? Are they producing what they should be? Are they breaking down often?

When you combine these two – ERP Equipment Utilization Tracking – you get a powerful tool. It means your central business brain (ERP) is constantly receiving and analyzing data from your machines. It’s like giving your ERP system eyes and ears on the factory floor, or in the field, or wherever your valuable assets are.

My "Before" Story: The Guessing Game and the Hidden Costs

Back in the day, before I truly embraced this concept, our approach to equipment management was, shall we say, "traditional." Which is a polite way of saying "guesswork and gut feelings."

We had spreadsheets, of course. Lots of them. Someone would manually log when a machine started, when it stopped, what it produced. But these logs were often incomplete, sometimes inaccurate, and always after the fact. By the time we compiled the data, the opportunity to make a real-time decision was long gone.

Here were some of our biggest pain points:

- Idle Machines, Invisible Costs: We had several pieces of expensive machinery. I knew they weren’t running 24/7, but I didn’t know how much they were sitting idle. Every hour a machine sat silent, we were losing potential revenue and still paying for its depreciation, space, and maintenance. It was like paying for a gym membership you never used, but on a much grander scale.

- Bottlenecks and Burnout: Some machines were constantly busy, leading to bottlenecks in our production line. Operators were stressed, and the machines themselves were showing signs of wear and tear prematurely. We’d scramble to shift workloads, but it was always reactive, never proactive.

- Surprise Breakdowns: Oh, the joys of an unexpected machine breakdown! Production grinds to a halt, orders are delayed, and the maintenance team goes into emergency mode. We knew breakdowns happened, but we had no way of predicting them or even understanding why they were happening so frequently on certain pieces of equipment.

- Poor Planning: Trying to schedule new projects or allocate resources felt like throwing darts in the dark. We didn’t truly know our capacity or where our available resources were. This led to missed deadlines and frustrated customers.

- No ROI Clarity: When it came time to justify purchasing a new machine, or even evaluating an existing one, I had no concrete data on its actual contribution. Was it truly worth the investment? My "gut" said yes, but my bank account wanted facts.

The Turning Point: A Glimmer of Hope

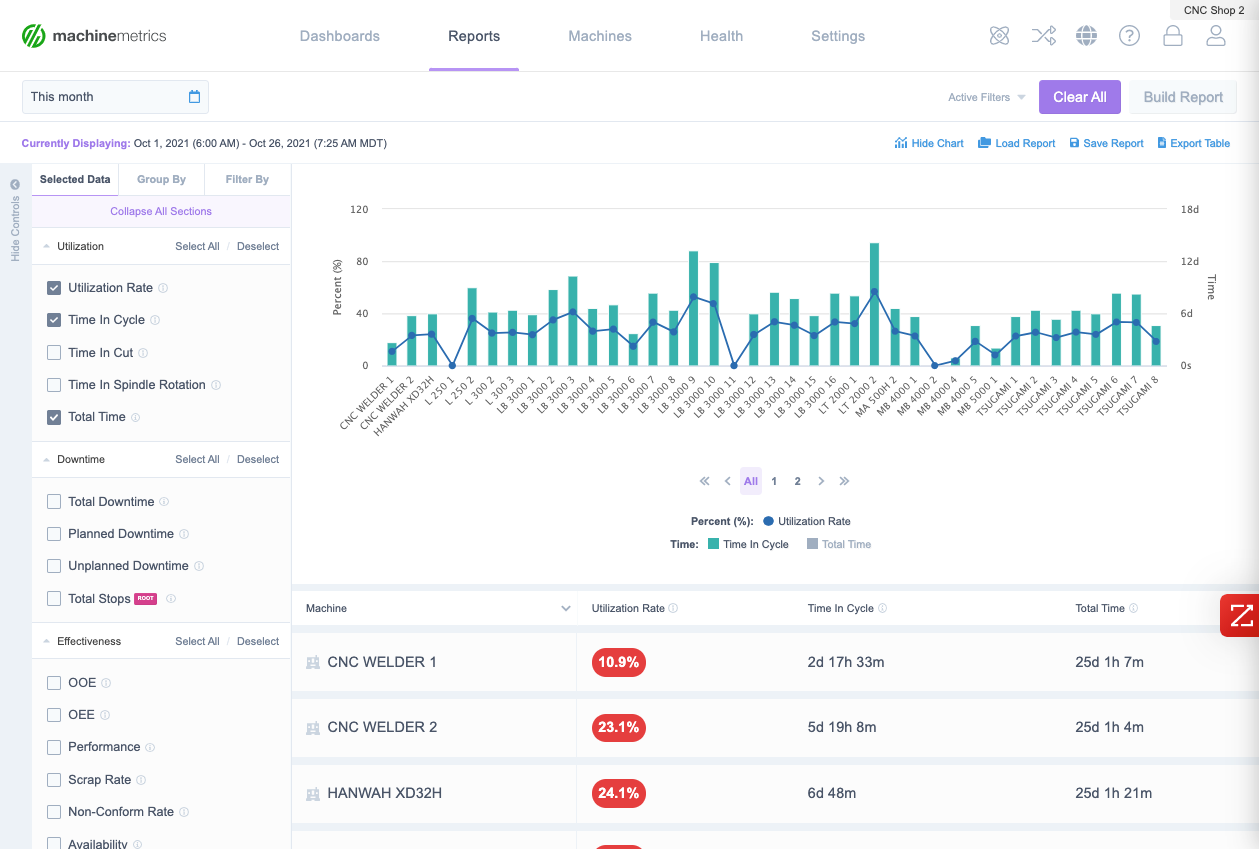

I remember attending an industry conference. A speaker was talking about "Industry 4.0" and "IoT" (Internet of Things) and how companies were using real-time data to optimize operations. It sounded futuristic, almost like science fiction. But then he showed a dashboard – a live, colorful display showing which machines were running, which were idle, and even their current output.

A lightbulb went off. This wasn’t just about fancy tech; it was about solving my problems. He mentioned how this was all integrated with their ERP system, turning raw data into actionable insights. This wasn’t just tracking; this was smart tracking.

I returned to my office buzzing with excitement and a healthy dose of skepticism. Could we do this? Was it too complicated for a company like ours?

How It Works (Simplified for the Curious)

We started small. The first step was understanding that modern equipment often has built-in sensors, or you can easily add them. These sensors collect data: is the machine on or off? What’s its current output? Is there an error code? Is it running at optimal speed?

This data, instead of being manually logged, is automatically fed into our ERP system. Our ERP then acts like a super-smart data analyst. It takes all those raw numbers and turns them into easy-to-understand reports and dashboards.

Imagine a car’s dashboard. It doesn’t just tell you if the engine is on; it tells you your speed, fuel level, engine temperature, and if anything is wrong. ERP Equipment Utilization Tracking does that for your entire fleet of machines, giving you a holistic view at your fingertips.

The "After" Story: Our Transformation and the Tangible Benefits

Embracing ERP Equipment Utilization Tracking wasn’t an overnight miracle, but the changes were profound and undeniable. Here’s what we started seeing: